The Aeronaut Side Curtain plug-in tool for Vectorworks allows the rapid design of patterns for truck side curtains by people with no real CAD experience. Flexible enough to cover almost all common types of truck curtains, the Side Curtain plug-in can give you a set of curtain patterns ready for cutting in less than a minute.

The Side Curtains plug-in tool is a mini-program which runs inside a powerful and easy to use off-the-shelf CAD package, Vectorworks. Complete cutting patterns for side curtains can be drawn with a few mouse clicks and dimension entries. If a design needs customising, you can use the normal tools of the CAD software to change a drawing. You of course use Vectorworks to design patterns for all your other 2D and 3D work too.

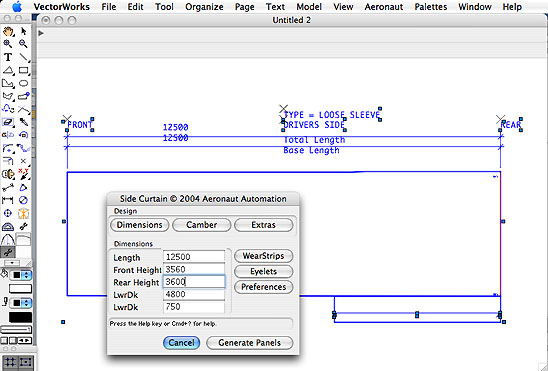

Starting with a group of basic design options, the user is guided through steps which define the shape of a truck curtain. The program uses default dimensions set by you, so many patterns can be completed in just a few clicks.

Pocketed and sleeved, or welded webbing curtain types are supported and different rig types such as rigid, semitrailer and B double.

The top and bottom camber of a curtain can be independently changed to suit the job, and wear strips created in the same drawing.

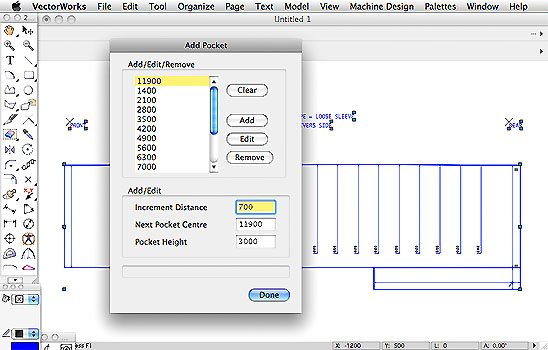

Webbing or pocket positions can be added automatically or one by one. In both cases, you can individually edit the positions and heights of pockets and eyelets.

As the main dimensions are entered, the base drawing is updated on screen, so it is easy to see where you are working and check for errors as you go. The Side Curtains plug-in can be customised so it works the way you want to. Default values can be entered, so when you begin to design a curtain, it's close to the correct size and has the correct options right away.

Eyelet shape is changeable in the Side Curtains plug-in. This makes it easy to customise the program to suit the type of eyelets you use & and rapidly change eyelet shapes if required. Whether you have a rotary blade or drag blade to cut the eyelets, you can choose a shape which ensures a clean cut-out on every one. A smooth oval, a plain rectangle or an octagonal shape.

If driver's and passenger side curtains are identical, you can save time by generating one pattern and flipping it in Vectorworks or Tangent. Asymmetrical patterns can be developed individually.

Once the side curtain pattern has been generated, it can be dimensioned and used as a factory work sheet, or sent to the customer for checking and approval.

Webbing pockets and wear strips can be drawn in Vectorworks or generated using Panelmonger, and nested together with the curtain patterns to get minimum fabric waste.

The Aeronaut Side Curtains plug-in, Tangent and an Aeronaut cutter can reduce a two man-hour job on hands and knees down to a six minute, one man operation, zero faults with economical waste management.

Cutters working with Truck Side Curtains are typically wide machines Normally 3.5 metres wide and around 17 metres long. Depending on the way eyelet reinforcement is done, a simple Elektron Mono WS may do the job, but normally fabricators use Elektron Quattro cutters, fitted with a drag blade for cutting eyelet holes, a pen for marking, a rotary blade cutter for high speed cuts and one or more drill punches.