Australia could be considered to be the birthplace of hang-gliding. It is also one of the best places in the world for paragliding and sport aviation. Since many of the people who work at Aeronaut as well as our contractors are involved in this sport, it is natural that we would develop machines and software to support a sport which we love.

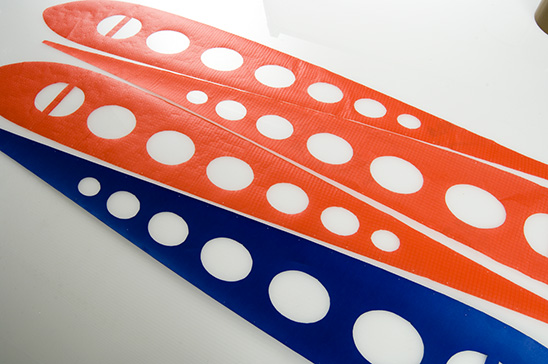

Flat-bed low-ply automated cutters are ideal for this work, where marking the fabric, accuracy of cut and multiple tools are required. It does not matter whether you need a cutter for making prototypes or for use in production, the requirements are the same accuracy, reliability, speed and repeatability.

An Aeronaut cutter can give you all this, with easy maintenance and a low purchase price too. And unlike many low-cost plotters, Aeronaut cutters have the accuracy required to make sure that one half-wing is the same shape as the other, so the glider flies straight first time.

Automated cutting is faster, more accurate and more economical than hand cutting. In fact one automated cutter can normally do the work of at least three people, but with zero mistakes and resulting benefits in product quality, reduced waste and improved profitability.

Aeronaut cutters have been designed from the beginning to work with industrial and recreational textiles. They are heavy duty machines capable of working 24 hours a day. Our blade cutters can put an enormous amount of force down on the cutting blade far more than most garment industry based machines.

Aeronaut has many cutters which are well suited to this type of work.

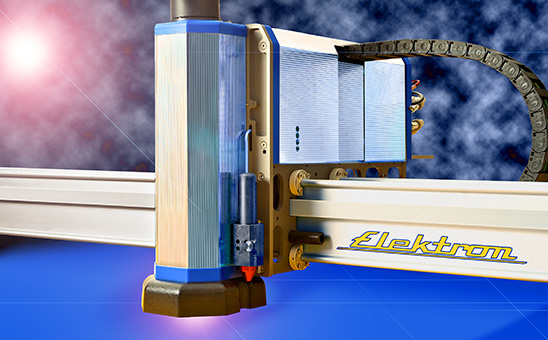

The Elektron Laser Z cutter was designed specifically for high-speed accurate cutting and edge sealing of the lightweight fabric used in paragliders and fabric covered aircraft. The Elektron Laser Z is very fast… ripstop Nylon can be cut and edge sealed at speeds over 1.2 metres per second. It's light, robust and extremely well priced. The perfect production tool.

For production work in larger paraglider factories it's common to stack-cut multiple layers of material and while the Elektron Laser Z works fine, the more powerful Elektron Laser ZT works a lot faster. Available in power outputs from 60 to 100 watts, this cutter has been bought by factories making everything from military parachutes and packs and aerospace re-entry parachutes to paragliders.

The Elektron Mono LC rotary blade cutter is a development of our legendary Maxis LC which has become the workhorse of sail makers. The Elektron Mono LC features Aeronauts revolutionary quick change cam-lock tooling which gives operators the ability to use a very wide range of tool options from 18mm, 28mm, and 45mm rotary blade cutters to drag knives, drill punches and creasing tools, extending the uses of the cutting system beyond whats offered on conventional plotter-cutters.

All Elektron automated cutters share a stiff and light gantry extrusion, high torque motors and extra-wide drive belts which have increased speed, acceleration and output. Design detail changes have allowed us to reduce the adjustment and calibration requirements to make the Elektron more robust and low maintenance than ever.