Aeronaut Automation - The Story So Far…

Aeronaut Automation is an Australian company specialising in the manufacture of wide span flatbed automated cutters. Our factory is situated in Terrey Hills, in a small industrial area in this otherwise residential suburb on Sydneys northern peninsular. The factory is about 25 minutes from Sydneys CBD and 12 minutes from the beach.

Unlike other companies manufacturing automated cutters, Aeronaut began as sailmakers… Aeronaut Sails, specialising in sails for round the world, single and shorted handed boats and fast multihulls. Unlike most sailmakers, we already had a metal-working lathe with a milling attachment in the kitchen. After moving to a bigger house, the lathe was moved into the spare bedroom. There was also nice room at the bottom level of the house which became the sail loft and after hours, the bedroom.

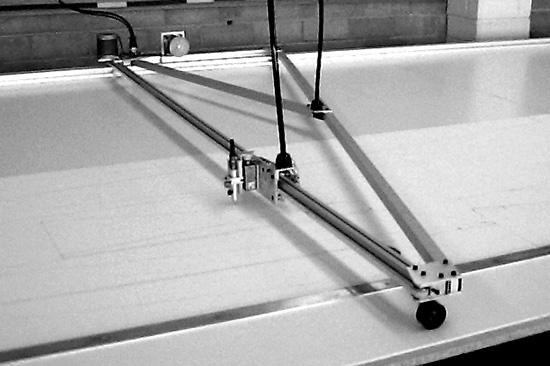

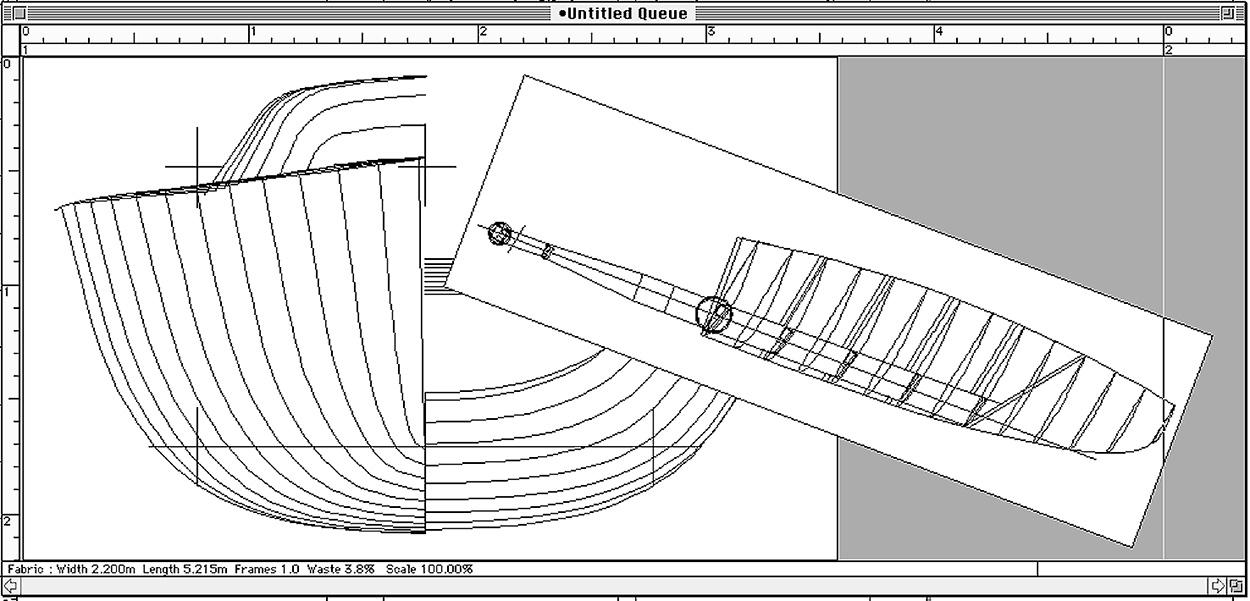

This arrangement wasn't entirely successful because half of the business owners objected to having to get up and move the mattress off the loft floor when the apprentice turned up for work. So we bought a basic pen plotter in 1987 leaving just the sewing machines in the bedroom and soon found that the software we had bought would design products like sails, but we couldn't cut a sail number let alone things like boom covers, bags and biminis. So we set about developing our own software, Panelmonger, for translating all sorts of files from sail and cad software into something we could plot were soon were selling Panelmonger to other sailmakers for file translations and our own plotter was hard at work doing things like full size boat hulls for boatbuilders.

We had an association with Sails Science in New Zealand and both of us realised that most sailmakers wanted a full package of software and plotter so we looked around for something which we could offer to the local market. Although the plotter we got was OK, like a lot of floor mounted plotters, it was quite flimsy and not as good as the Axon plotter we already owned. Many of the plotters we imported from the UK were damaged in transit by things like the heavy transformer breaking loose and clearing out inside the control box. There wasn't much support for configuring the software either, so we got used to a lot of repair and improvements. And then we decided to make our own.

Two of the plotters we sold were installed miles away - 800km and 1600km. If and when a wire failed and had to be fixed, as it did on both, we were working for a loss. This focussed us on the importance of designing reliability in right from the start (and only using good quality robotic cables!)

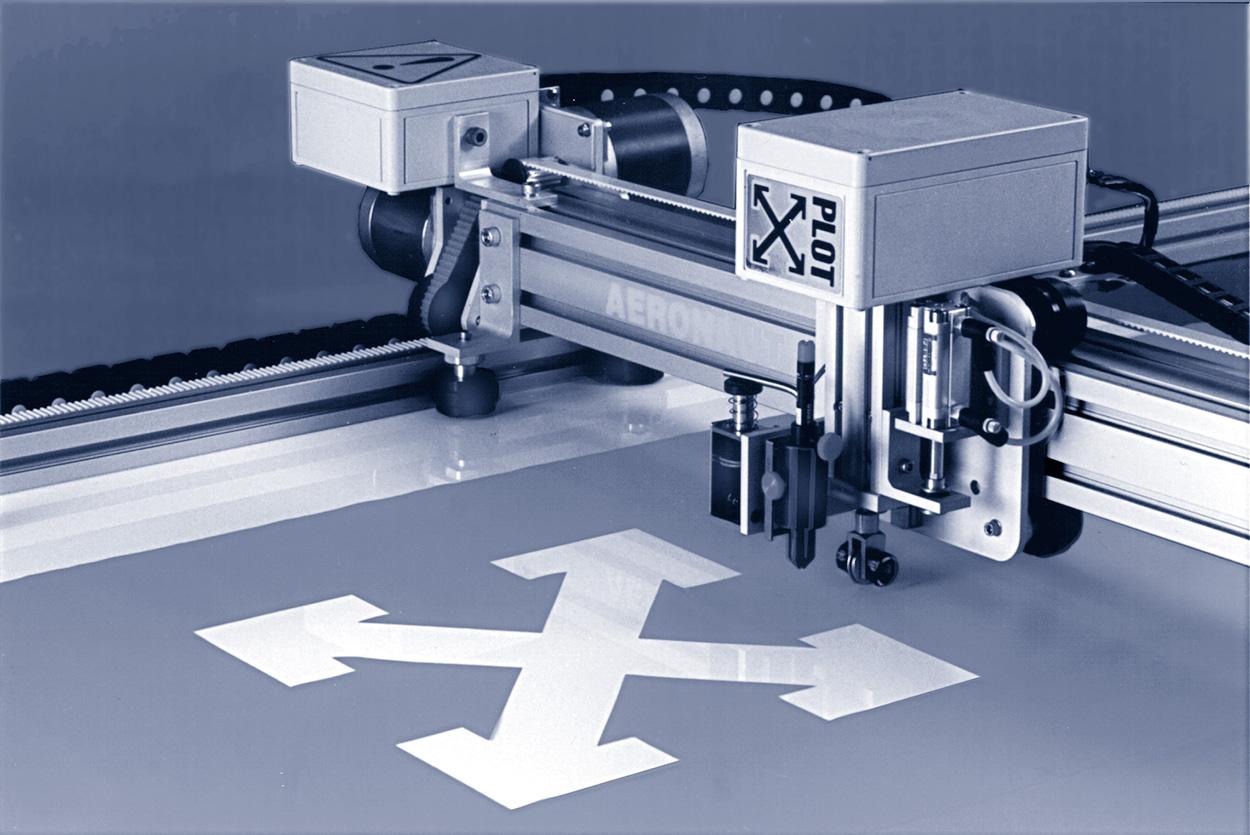

The change from Aeronaut sails to Aeronaut Automation came about when a local sailmaker said that he wanted to buy a cutter but he wanted us to make it for him. And he sent a cheque, which sat on the office desk for a couple of months until the kids complained because they couldn't have chips and ice cream on big a day out. The kids had somehow appeared while we were making software and plotters.

After selling six cutters in five weeks to various marine businesses we decided that was where the future lay for Aeronaut.

Products

Technology

Special Machines

Matrelec HF Welders

Applications

Company

News

Contact Details

Aeronaut Automation

4-6 Tepko Road,

Terrey Hills,

New South Wales 2084

Australia.

Hours: 8:00 - 17:00 Australian Eastern Standard Time

Tel: +612 9450 0800

Sales: Sales@Aeronaut.org

Admin: Admin@Aeronaut.org

Support: Support@Aeronaut.org

Tech: Tech@Aeronaut.org