Aeronaut Automated Cutting Systems for Outdoor Shade and Awnings

One of the first five automated cutters made by Aeronaut was bought by an outdoor awnings manufacturer. Within a year, the company had grown from 2 people to seven people because the time saved cutting fabric was used for sales and installations. Since then, Aeronaut has gone on to lead the field in making cutters and cutting system add-ons for this industry.

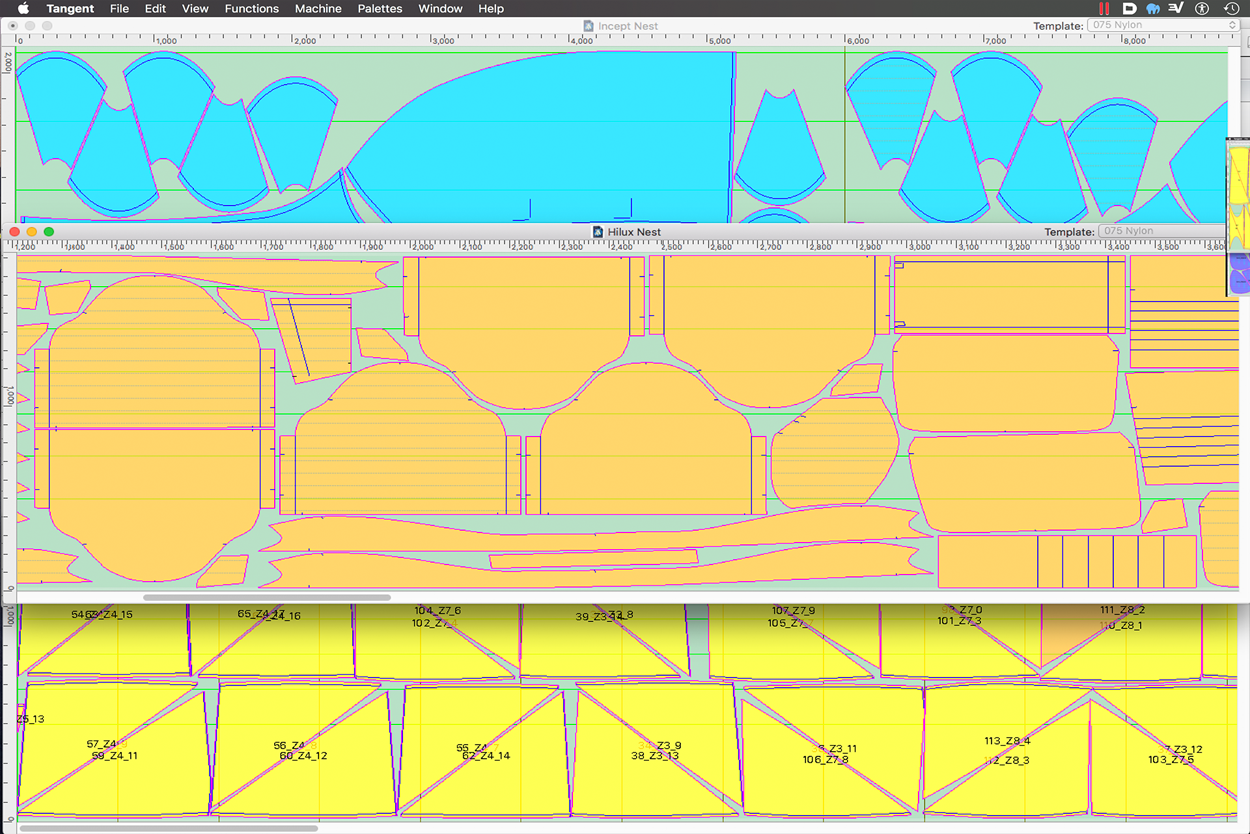

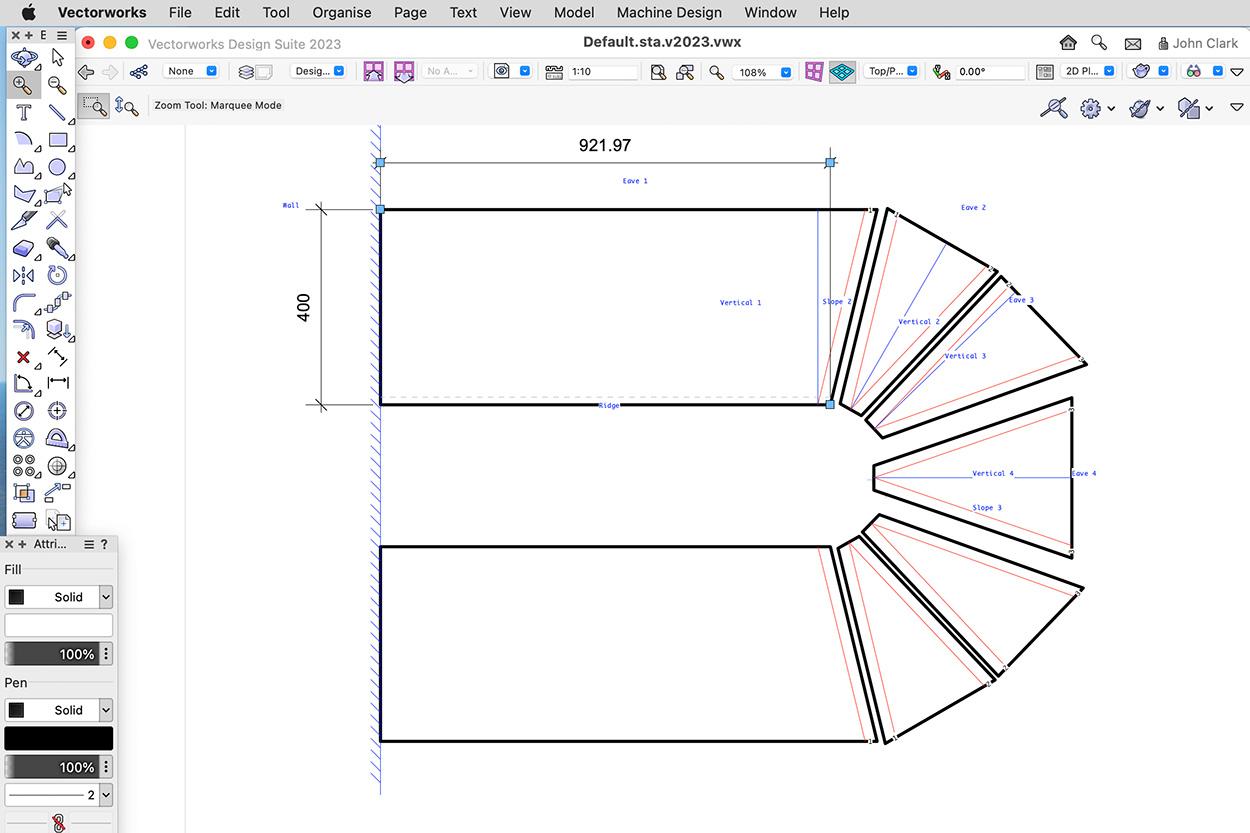

Many outdoor shade and awnings businesses make a wide range of products from conventional awnings to shade sails, small tension membranes and shade structures with fabrics from shade mesh to PVC. While knitted shade fabrics don't require much accuracy, other products need the accuracy you get from a flatbed cutting table. In fact some fabricators have very wide cutting tables so they can join panels together and cut the finished product from the joined fabric.

A 28mm rotary blade cutting tool is will cut 95% of the fabrics used in outdoor awnings and shade structures. Vacuum hold down is necessary to get the accuracy on most fabrics but shade mesh can normally be cut with good enough accuracy for the finished product without using vacuum.

Accurate marking of seam lines is essential to get accurate joining of patterns using a marker which either fades rapidly in sunlight or which can be wiped off the fabric.

Machine vision systems like SiliconEye can be used for tracing and digitising patterns, nesting into offcuts and aligning cut profiles for cutting the finished product from joined fabric. SiliconEye can even be used for pre-delivery quality control to confirm the dimensions and finish of a product.

The Tools of Your Trade

Essential

Aeronaut's Elektron Mono WS with Cam-lock quick change tooling is a hugely popular cutter for outdoor shades and awnings. The Elektron Mono WS can be made up to 6.5 metres wide to span the widest fabrics or joined materials. A heavy-duty machine, the Elektron Mono WS has the power to do the job, and the reliability to keep working with minimal maintenance.

Versatility

The Elektron Quattro multi-tool cutter can carry up to four steered Cam-lock quick change tools including rotary blades, drag blades and drill punches which are switched by software when cutting. This means you can handle the widest range of work, efficiently and accurately whatever the future holds in outdoor awnings and shade products.

The Elektron Mono WS and Elektron Quattro are high specification automated cutters and can be fitted with the full range of Aeronaut's accessories including inkjet print heads, inkjet pens, Cyclops machine vision cameras.

Cam-lock Quick Change Tools

On the Elektron Quattro, tools are changed automatically under software control. However Cam-lock tools can be changed by hand in a few seconds so you can fit the tools you need, when you need.

The Cam-lock tool range includes 18mm, 28mm and 45mm rotary blades, tangential or drag knives with various depth stops for normal and high friction materials, creasing and scoring tools in a wide range of profiles and drill-punch sizes from pin to over 25mm. Drill-punch inserts are easy to sharpen and exchange.

Software, Nesting and Technology

Contact Aeronaut

Get the facts from the factory direct. If you want advice on automated cutting, an offer on a complete cutting system or to arrange a demonstration, just ask!

Products

Technology

Special Machines

Matrelec HF Welders

Applications

Company

News

Contact Details

Aeronaut Automation

4-6 Tepko Road,

Terrey Hills,

New South Wales 2084

Australia.

Hours: 8:00 - 17:00 Australian Eastern Standard Time

Tel: +612 9450 0800

Sales: Sales@Aeronaut.org

Admin: Admin@Aeronaut.org

Support: Support@Aeronaut.org

Tech: Tech@Aeronaut.org