Aeronaut Automated Cutting Systems for Parachutes

Military, Mars lander, aerospace, reentry and cargo…

Aeronaut laser cutters are the automated cutting machine of choice for parachute manufacturers around the world. Military, aerospace, reentry and cargo… they're all made on Aeronaut cutters. In fact one of our customers has a parachute on Mars.

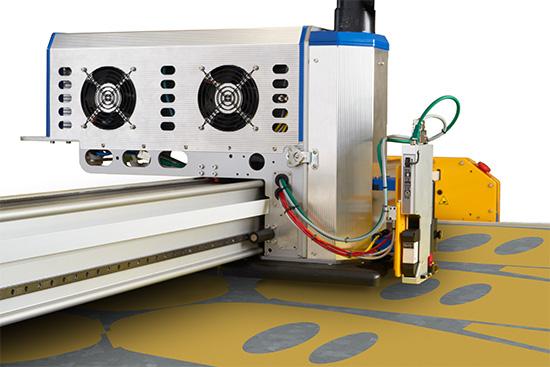

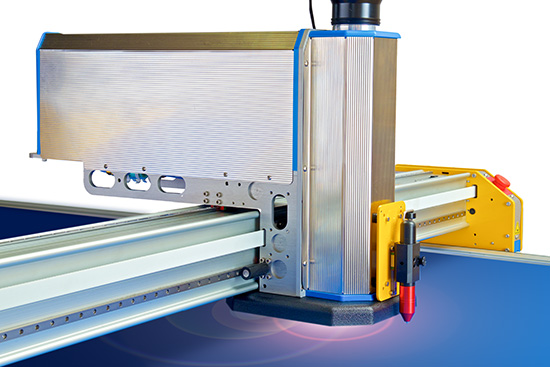

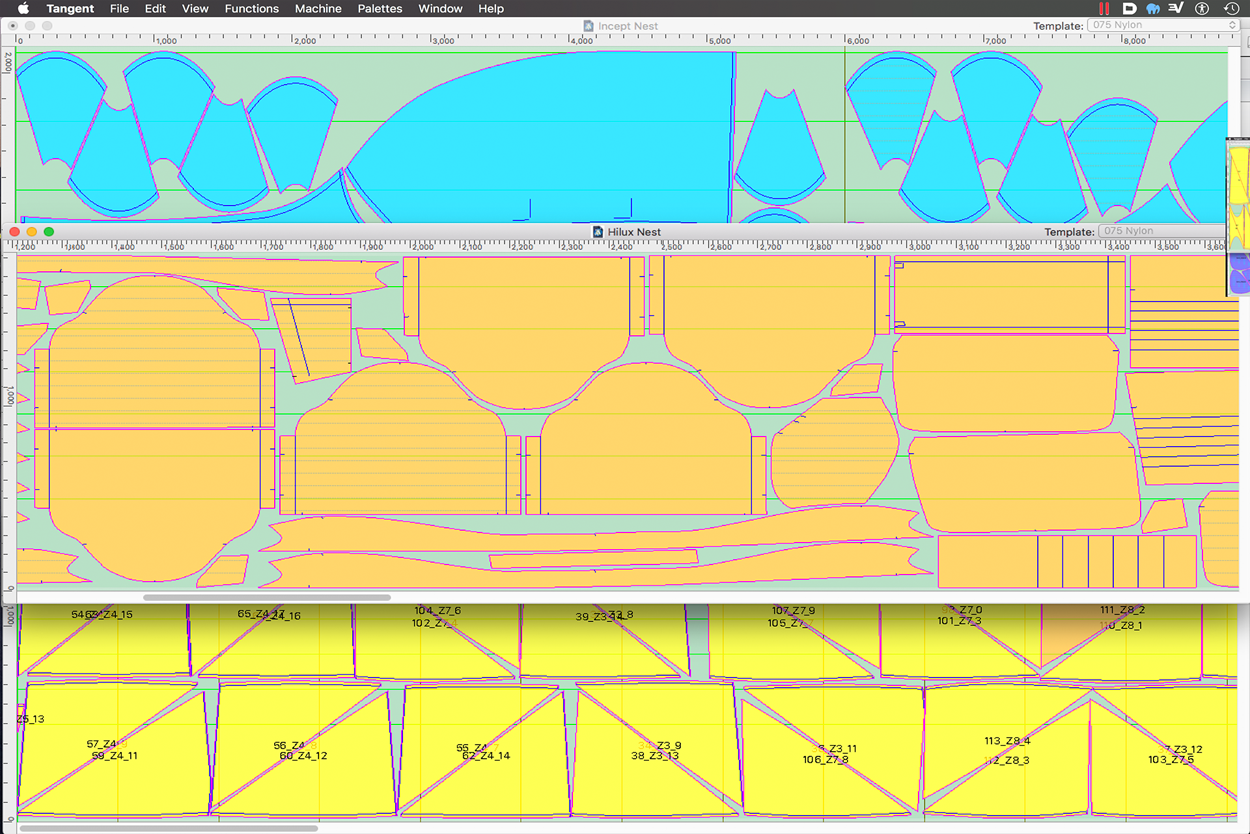

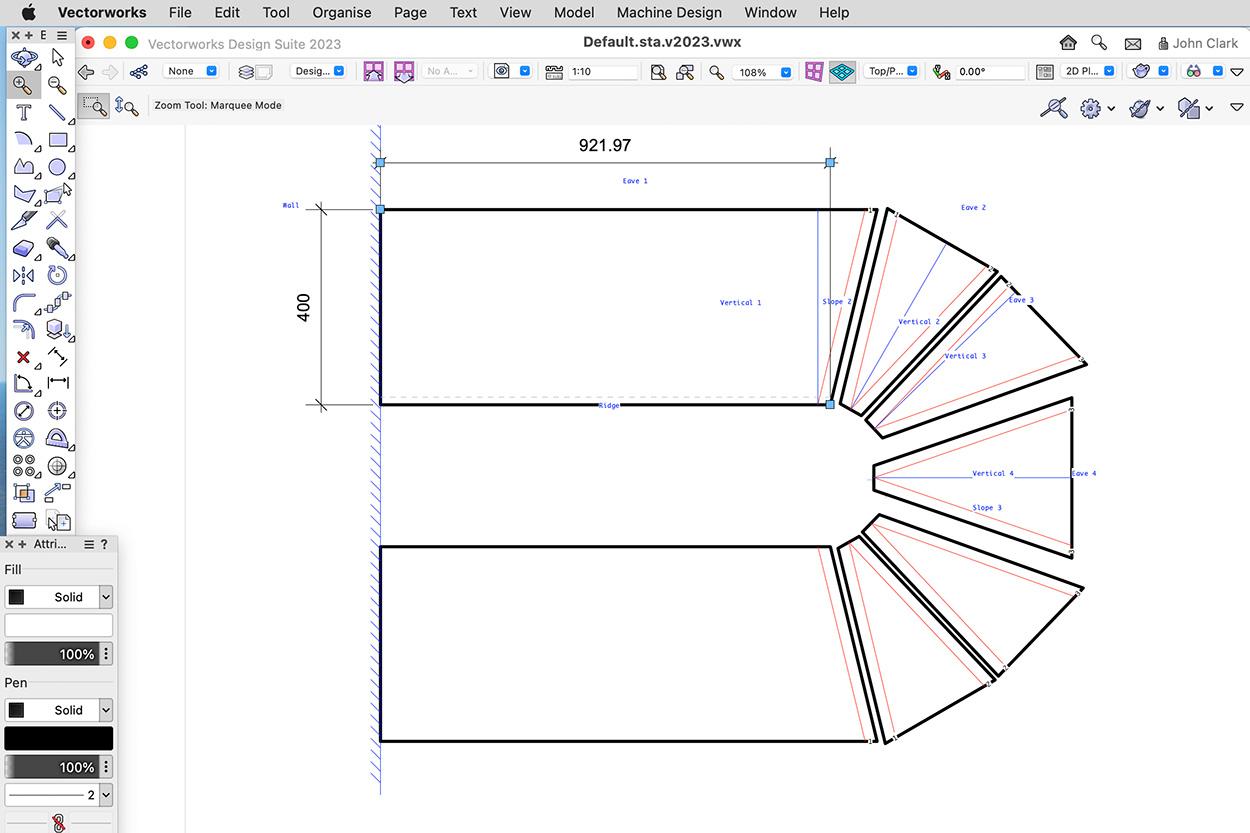

Laser cutters are perfect for mil-spec parachute manufacture. A flatbed laser cutting table guarantees an all-round sealed cut edge, something you cannot get on a conveyor cutter. Inkjet print heads label accurately and quickly with tested, approved ink.

With a flatbed laser cutter and an inkjet print head, nothing touches the material while it's being cut. This means no movement of the material with wrinkles and bubbles pushed across the table. The vacuum bed holds the patterns securely meaning cutting can be a productive, stress free, hands off operation in small or large factories.

The Tools of Your Trade

Aeronaut's "All Metal" CO2 laser cutters will cut the full range of parachute materials including Nylon, Cordura, Dyneema, Kevlar, foam and almost all synthetic fabrics. Aeronaut manufactures low, medium and high power laser cutters using US made laser tubes with exceptionally long service life, all of which are suitable for parachute and associated equipment manufacture.

Low power laser cutters are lighter weight and more agile than high power laser cutters so they're ideally suited to cutting parachute Nylon. The higher power lasers come into their own when cutting other materials for harnesses and containers etc. where the higher power level means better cut speeds on heavier materials.

Essential

Aeronaut's Elektron Vi30 Laser is a low power laser able to cut most parachute Nylon at production speeds of over 1000mm/sec (39"/sec). Since the laser and chassis are light, the Elektron Vi30 laser is an agile machine capable of high throughput. It's made to the same industrial strength standards as Aeronaut's higher power lasers and can be fitted with the essential accessories like and inkjet print head for reliable high-speed marking.

Production

Elektron Ti60 - 100 lasers are production lasers suitable for all parachute work. Fitted with a long-wheelbase stable chassis, these medium power lasers are light enough for high speed cutting and powerful enough for the other materials used in parachute manufacture. The Elektron Ti60 - 100 range is available in air or water cooled versions for all environmental conditions and can be fitted with the essential accessories like and inkjet print head for reliable high-speed marking.

Power

Elektron P100 - P250 lasers are high power CO2 pulse lasers able to handle the heaviest materials at production cutting speeds. The 100 watt versions are light enough for efficient cutting of parachute Nylon and have an exceptionally clean cut on heavier materials, even foam, used for containers and harnesses. The P series lasers are only available in water cooled versions and can be fitted with the essential accessories like and inkjet print head for reliable high-speed marking..

Software, Nesting and Technology

Contact Aeronaut

Get the facts from the factory direct. If you want advice on automated cutting, an offer on a complete cutting system or to arrange a demonstration, just ask!

Products

Technology

Special Machines

Matrelec HF Welders

Applications

Company

News

Contact Details

Aeronaut Automation

4-6 Tepko Road,

Terrey Hills,

New South Wales 2084

Australia.

Hours: 8:00 - 17:00 Australian Eastern Standard Time

Tel: +612 9450 0800

Sales: Sales@Aeronaut.org

Admin: Admin@Aeronaut.org

Support: Support@Aeronaut.org

Tech: Tech@Aeronaut.org