The Elektron Mono LC Blade Cutter

Accurate, Powerful, Reliable and Exceptional Value For Money.

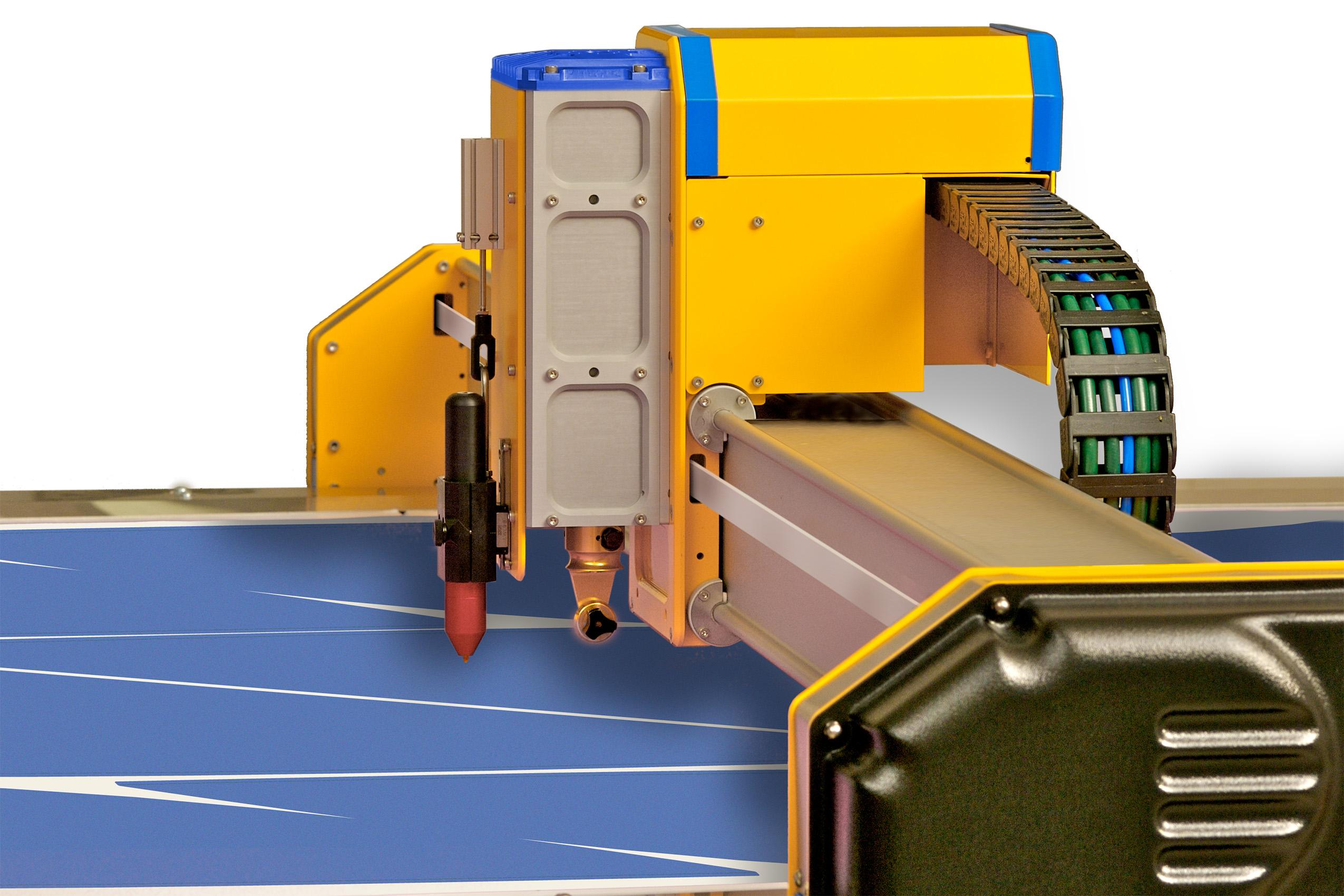

The Elektron Mono LC automated cutting system from Aeronaut is a simple single quick-change tool cutter designed to handle the difficult fabrics and the toughest workloads. It is the most affordable option in Aeronaut's range of plotter cutters, available with full turnkey installation.

The best performing and best value entry level automated cutter on the market.

Made in cut widths less than 2.05 metres (80"), the Elektron Mono LC has been designed without compromise, offering exceptional performance and a long service life. All machines in the Elektron range share the same heavy-duty chassis, designed to span 6.5 metres.

Featuring Aeronaut's Cam-lock quick-change tooling system, tools from blades to drill punches can be fitted and changed in seconds. These tools lock positively and firmly in place, ensuring perfect alignment of blade height and angle.

You can fit a wide range of tools to the same machine, including rotary (pizza) blade holders in 18mm, 28mm, and 45mm diameters, drag blade holders, creasing tools, and even a Z-axis drill punch. This feature maximises the machine’s performance and versatility.

All Aeronaut cutters are equipped with a pen adaptor, capable of holding a wide range of markers, from ballpoint pens to paint markers. This adaptor allows you to change marker types without altering critical seam allowances.

When working with materials like shade cloth, canvas, and PVC fabric, a rotary blade can perform 95% of the tasks and with Cam-lock tools, you can fit any other tool in a few seconds.

The Elektron Mono LC is quiet, remarkably smooth-running, and powerful. It exceeds industry standards for speed, accuracy, and repeatability – but without the industry-standard price tag.

To keep costs down, the Elektron Mono LC does not have the wiring capacity for extras like inkjet heads or Cyclops machine vision. If these are essential, see the Elektron Mono WS.

Features

Cam-Lock quick-change tooling system

Supports rotary (pizza) blade holders (19mm, 28mm, 45mm), drag blades, creasing tools, and a Z-axis drill punch for ultimate flexibility.

Swap between blades, drill punches, and other tools in seconds for maximum safety and efficiency.

Heavy-Duty Chassis

Designed to cut the widest fabrics and handle the toughest materials with precision and ease.

Built to working widths of 2.05 metres, providing strength and stability for demanding workloads.

Concentric Pen Adaptor for Accurate Marking

Compatible with a wide range of markers (ballpoints, paint markers, etc.), enabling easy marker type changes without affecting seam allowances.

Optional Higher Tool-Pressure Version

For applications requiring extreme pressure, such as cutting and creasing thicker materials.

Smooth and Quiet Operation

Runs quietly with remarkable smoothness, making it suitable for any workspace.

Advantages

Cost-Effective Solution

The most affordable plotter-cutter in the Aeronaut turnkey range, providing high-end performance at an accessible price point.

Long Service Life

Engineered without compromise, the Mono LC is built to last, delivering reliable performance over decades.

Future proof

Rapidly change between cutting tools to handle a variety of materials and tasks with ease, now and in the future.

Very low maintenance

Compared with entry-level cutters from other manufacturers which need heavy maintenance every few years, the Elektron Mono LC is almost maintenance-free.

Superior Speed and Accuracy

The unique design ensures faster cutting and greater precision compared to other single-steered plotter cutters.

Exceeds Industry Standards

Designed to meet and surpass industry standards for entry-level cutters for speed, accuracy, and repeatability, offering exceptional value without the hefty price tag.

Cam-lock tools can be changed by hand in under 15 seconds so you can fit the tools you need, when you need.

If your work doesn't need more than a few tools and you're OK with changing them manually, then the Elektron Mono should be a serious consideration.

The Cam-lock tool range includes 18mm, 28mm and 45mm rotary blades, tangential or drag knives, creasing and scoring tools and a wide range of drill-punch sizes from pin to over 25mm.

Industries

Many industries only use narrow fabric widths… 2 metres, 6 foot, 1600mm and so on. A lot of fabrics are available in both narrow and wide widths. If this applies to your industry, a narrow cutting table might make good sense, always bearing in mind that you get better nesting efficiency with wider fabrics and longer nesting frames.

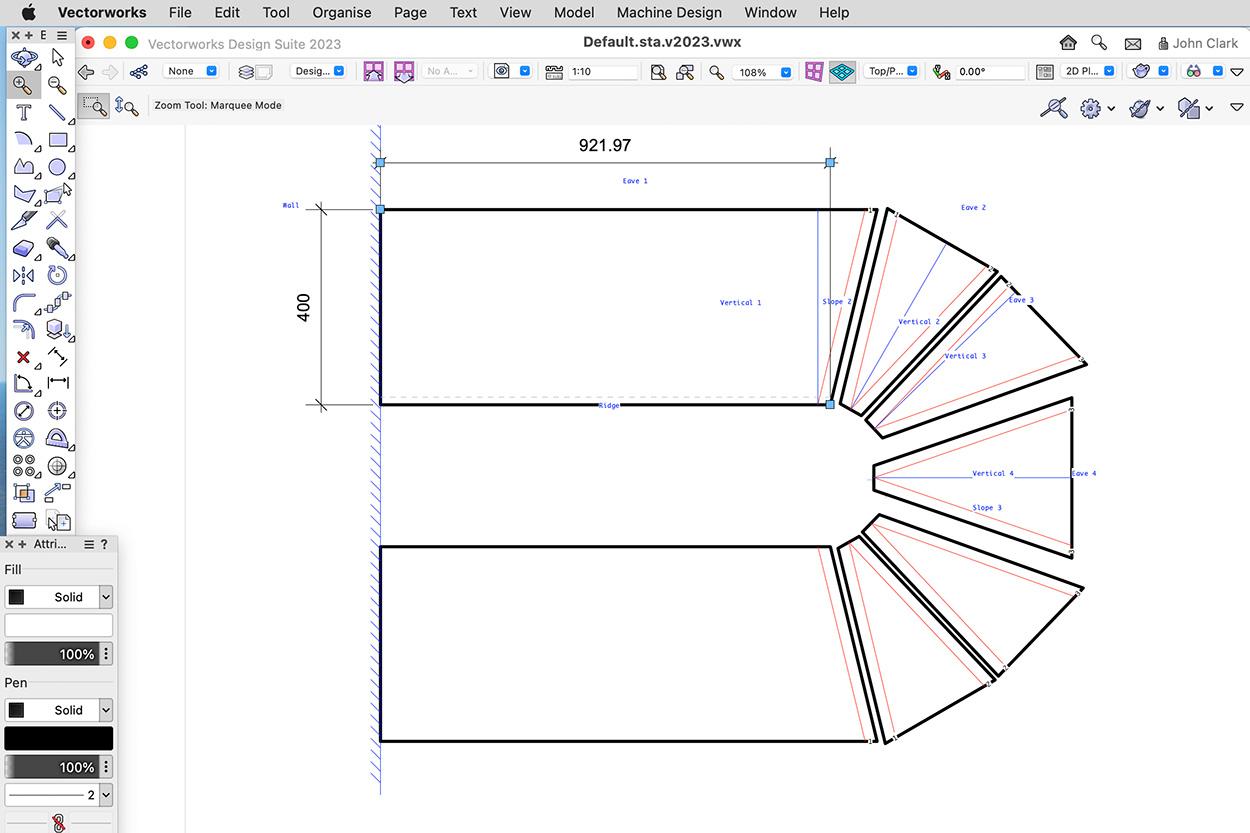

Paragliders & hang gliders

Laser cutters may be the best option for these industries but if you are on a budget and want the affordable price and versatility of a blade cutter, the Elektron Mono LC is a great cutter.

Pool liners and covers

If you're working with pool liner and cover materials in widths under 2 meters, then the Elektron Mono LC is a no compromise entry level cutter, entirely suitable for this work.

Upholstery & trimming

If your materials are under 2 metres (80") wide and you rarely need punches, creases or cutting tools for small details, then the Elektron Mono LC is a great and affordable choice.

Sailmaking and Marine

Sailcloth is all narrow width and most other fabrics used in the marine industry are available in narrow widths. The Elektron Mono LC has all the accuracy and reliability you need.

Increase Productivity

Reduce Waste

Reduce Mistakes

Software, Nesting and Technology

Why Automate?

Most of the benefits of automation are obvious, others less so.

- Automation will increase productivity without increasing staff numbers while at the same time reducing waste, mistakes and staff stress at busy times.

- If you don't want growth, automation can let you produce the same number of good quality products with fewer staff.

- Automation reduces your reliability on key workers and conventional skills while attracting another generation of workers who might be entirely happy with computers but less so pushing a pair of scissors.

- Automation adds value to a business since the IP, designs and patterns are all digitised and can be stored off-site.

- Cutting accurate patterns no longer depends on key workers. Aeronaut cutter are easy to operate so many people can run a cutter and saved jobs can be easily recut.

- Automation means you can do more markings and more markings means faster, more accurate and more reliable assembly. The cutting and marking process may take a while longer but the sewing, welding or bonding operations are much faster.

Why Aeronaut?

- Apart from the obvious reason that Aeronaut has some of the best people around in sales, design, software and support…

- Aeronaut cutters are legendarily reliable. We've got dozens of cutters over 20 years old which are still doing the same reliable job for their owners.

- The cost of ownership of an Aeronaut cutter is very low. Upgrades, spares and service are readily available even for 30 year old machines.

- Over a third of new machine orders are from customers who already own at least one Aeronaut cutter, something which applies across the board from NASA contractors to the boat cover maker down the road.

- Aeronaut's cutters are rationally designed machines. As one customer said, "if we'd bought another make of cutter, we'd have spent more on plastic covers than we did on our whole machine".

- Aeronaut cutters may be overbuilt, like a '70s Mercedes and there's a sense of security in knowing that your 3 metre wide cutter is also working somewhere else at 6 metres wide.

- If it's yellow, it doesn't break! 90% of components are made in-house on one of 5 CNC machines, most of which are German 5 axis machining centres. If we made it once, we can make it again.

Contact Aeronaut

Get the facts from the factory direct. If you want advice on automated cutting, an offer on a complete cutting system or to arrange a demonstration, just ask!

Products

Technology

Special Machines

Matrelec HF Welders

Applications

Company

News

Contact Details

Aeronaut Automation

4-6 Tepko Road,

Terrey Hills,

New South Wales 2084

Australia.

Hours: 8:00 - 17:00 Australian Eastern Standard Time

Tel: +612 9450 0800

Sales: Sales@Aeronaut.org

Admin: Admin@Aeronaut.org

Support: Support@Aeronaut.org

Tech: Tech@Aeronaut.org