Automated Cutters for Truck Side Curtains and Tautliners

Aeronaut has been making flatbed automated cutting systems for work with truck side curtains and taut liners for almost 30 years. It's an industry perfectly suited to wide span cutters, where a job which might take 2 people a full 2 hours can be reduced 10 minutes. Reliable, error free, productive cutting reduces stress and worker fatigue so it's as much appreciated by your staff as your accountant.

Modern side curtains with digitally printed graphics are best cut with a modern automated cutting system where machine vision systems can easily align the cut profile with the printed material making sure that the cut is right first time. Aeronaut's low-cost Cyclops gantry mounted camera can align a cut profile to digitally printed material automatically, but even done manually, it's half a minute's work on a big table.

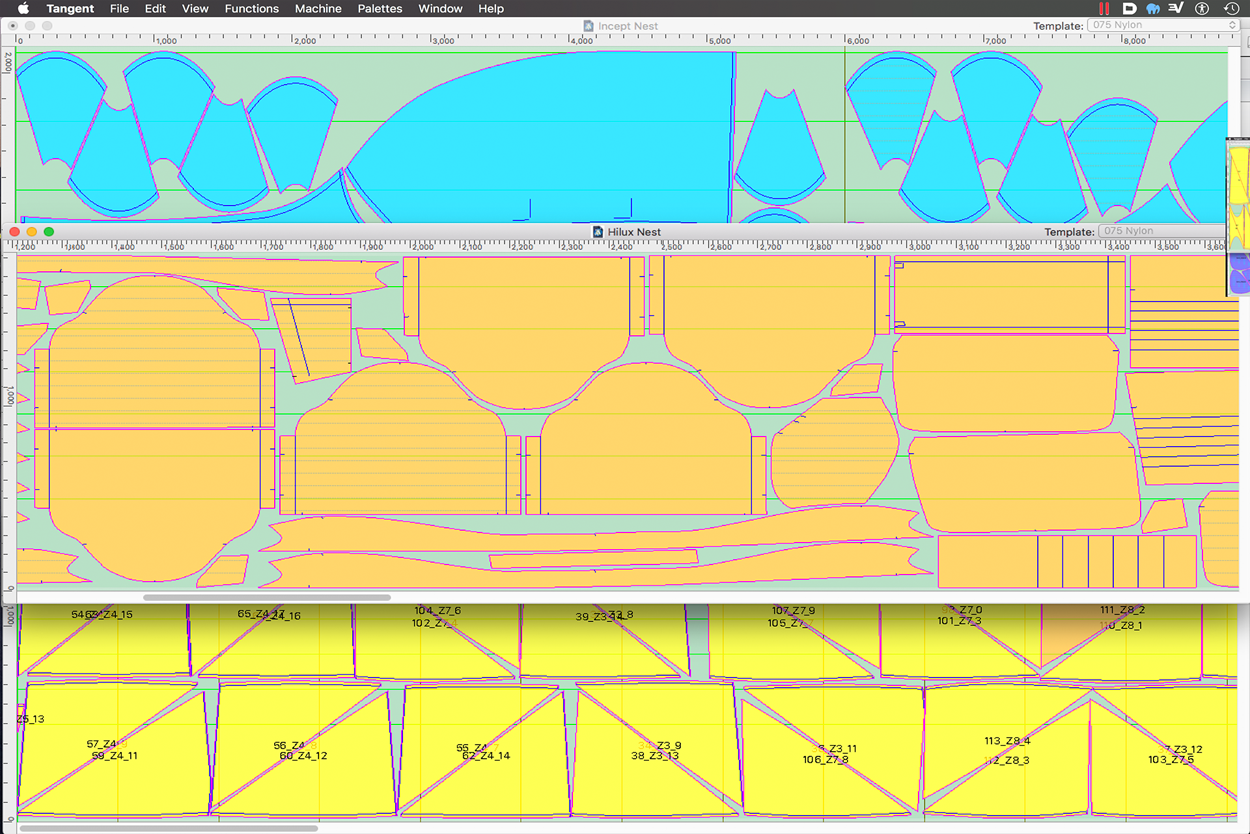

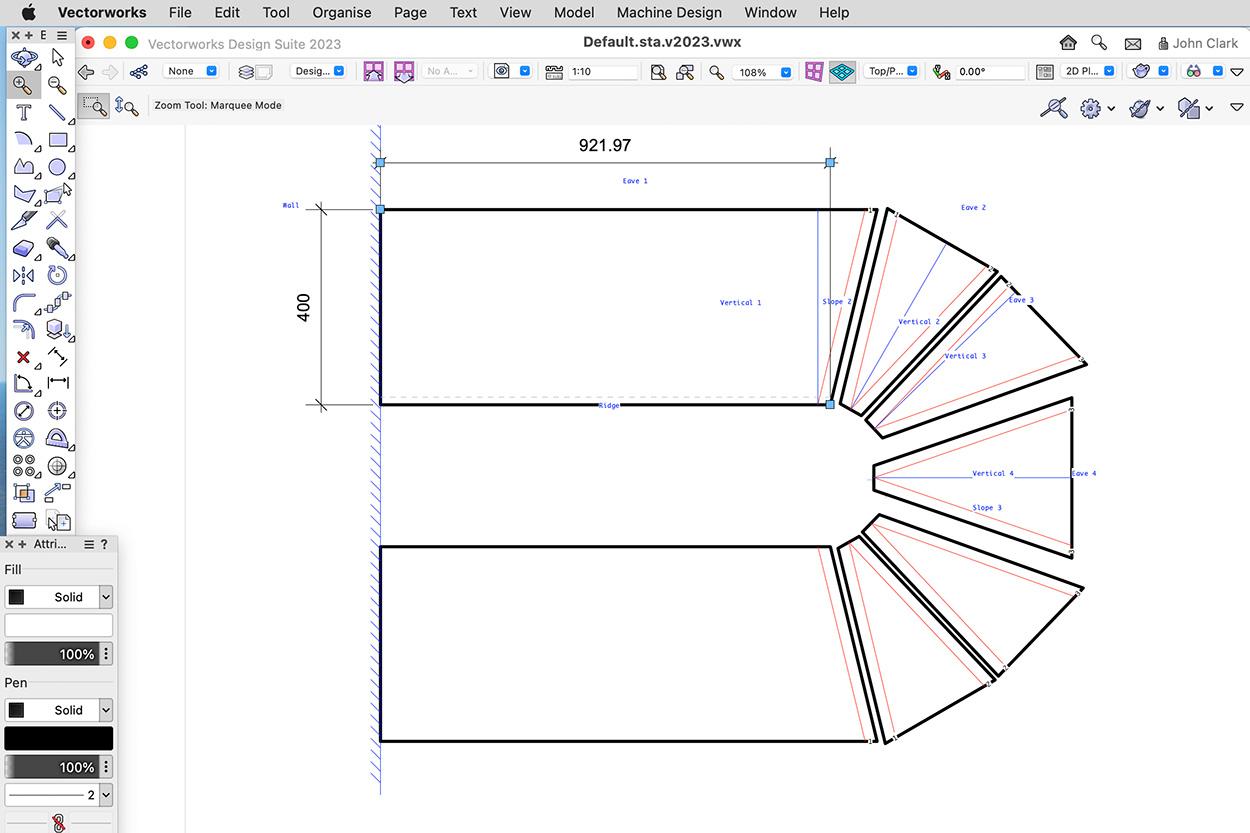

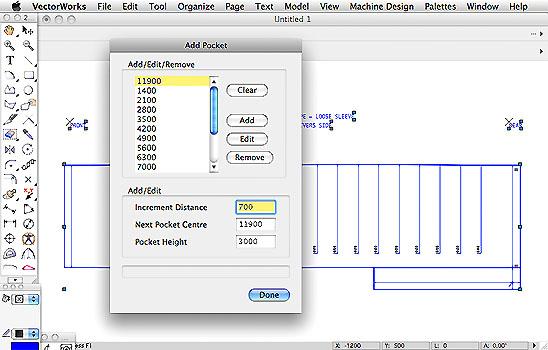

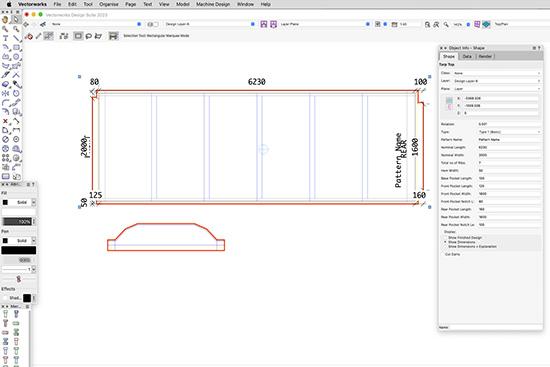

Rapid pattern design for truck curtains and tautliners can be done with Aeronaut's parametric CAD plug-ins. These simple tools allow information from a factory's order system to be entered either manually or automatically into a plug-in tool which creates a complete set of cutting patterns for an order. The process doesn't require any special CAD skills and can be done in a minute or two by anyone with basic computer skills.

Of course an Aeronaut automated cutting system can do far more than just truck side curtains. Any large scale textiles work in the transport industry as well as rural tarpaulins, dam liners and containment products can be easily made using the same tools.

The Tools of Your Trade

Essential

Aeronaut's Elektron Mono WS with Cam-lock quick change tooling is the essential cutter for truck side curtains, tarps, covers, canvas and PVC. The Elektron Mono WS can be made up to 6.5 metres wide to span the widest fabrics or joined materials. A heavy-duty machine, the Elektron Mono WS has the power to do the job, and the reliability to keep working with minimal maintenance.

Versatility

The Elektron Quattro multi-tool cutter can carry up to four steered Cam-lock quick change tools including rotary blades, drag blades and drill punches which are switched by software when cutting. This means you can handle the widest range of work, efficiently and accurately whatever the future is in truck and transport products.

Cam-lock Quick Change Tools

Cam-lock tools can be changed by hand in a few seconds so you can fit the tools you need, when you need. On the Elektron Quattro, tools are changed automatically under software control.

The Cam-lock tool range includes 18mm, 28mm and 45mm rotary blades, tangential or drag knives with various depth stops for normal and high friction materials, creasing and scoring tools in a wide range of profiles and drill-punch sizes from pin to over 25mm. Drill-punch inserts are easy to sharpen and exchange.

Software, Nesting and Technology

Contact Aeronaut

Get the facts from the factory direct. If you want advice on automated cutting, an offer on a complete cutting system or to arrange a demonstration, just ask!

Products

Technology

Special Machines

Matrelec HF Welders

Applications

Company

News

Contact Details

Aeronaut Automation

4-6 Tepko Road,

Terrey Hills,

New South Wales 2084

Australia.

Hours: 8:00 - 17:00 Australian Eastern Standard Time

Tel: +612 9450 0800

Sales: Sales@Aeronaut.org

Admin: Admin@Aeronaut.org

Support: Support@Aeronaut.org

Tech: Tech@Aeronaut.org