Aeronaut Cutting Systems for Canvas and PVC

Canvas and PVC textiles are used in a huge range of products made by specialised manufacturers all over the world many of whom rely on Aeronaut automated cutters to get the job done.

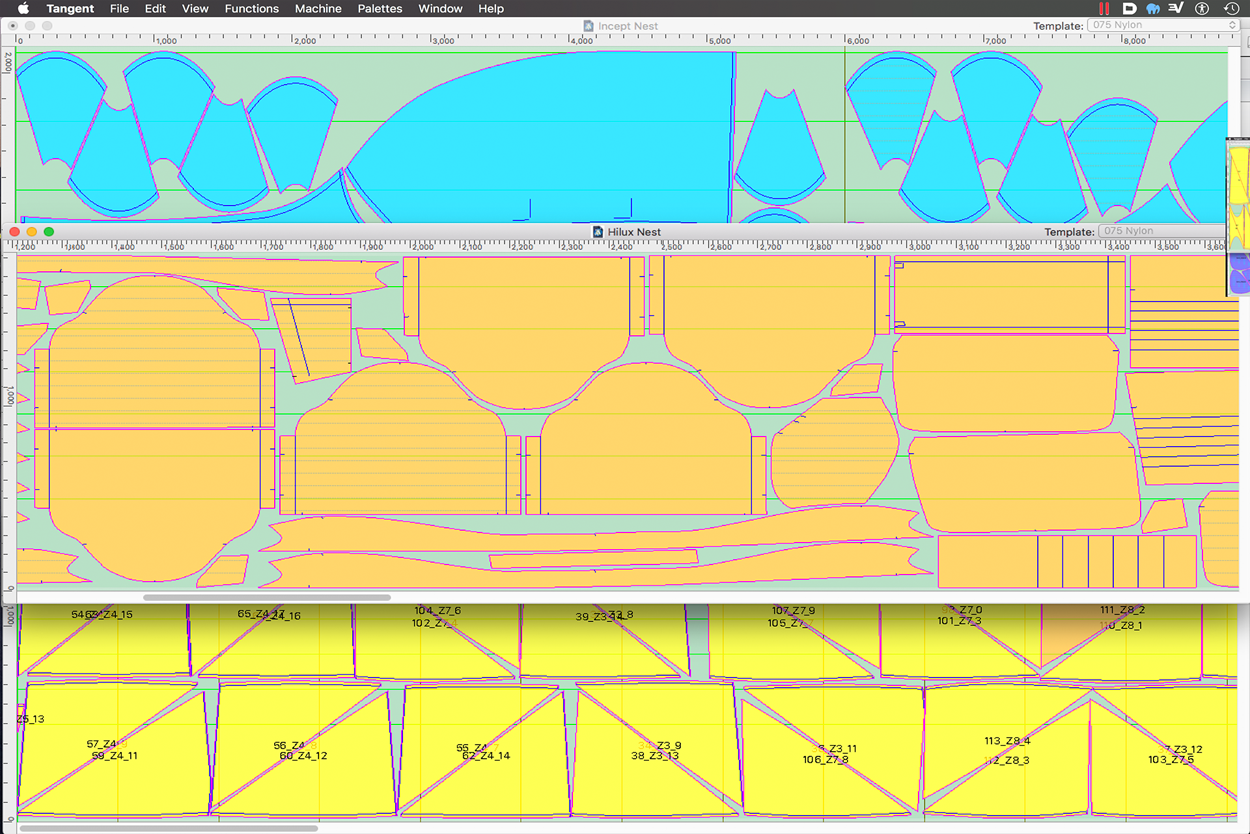

Almost all of the materials in the specialised textiles field present no problems in automated cutting, creasing or punching. Comprehensive marking that you can only do on a single ply cutter is often the critical part of the cutting process because these detailed products often have a lot of fittings and accurate marks make fabrication quick and mistake free. Aeronaut's concentric marker holders and inkjet print head options make marking quick, accurate and easy.

Camper trailers, RV and outdoor equipment needs to be accurately made so it fits the hardware properly. Wide fabrics need wide cutters and complicated patterns need multi-tool cutters like the Elektron Quattro for maximum productivity.

Motor trimming can use a wide range of materials from canvas and PVC through to carpet and leather. Aeronaut has versatile machines to automate the cutting and machine vision digitising systems like SiliconEye to handle the patterning.

Smaller canvas and PVC products like bags, mining equipment and covers can often be made from narrow materials on a smaller cutting table. Here, machines like the Elektron Mono LC and Mikron 2 can be a good choice of cutter.

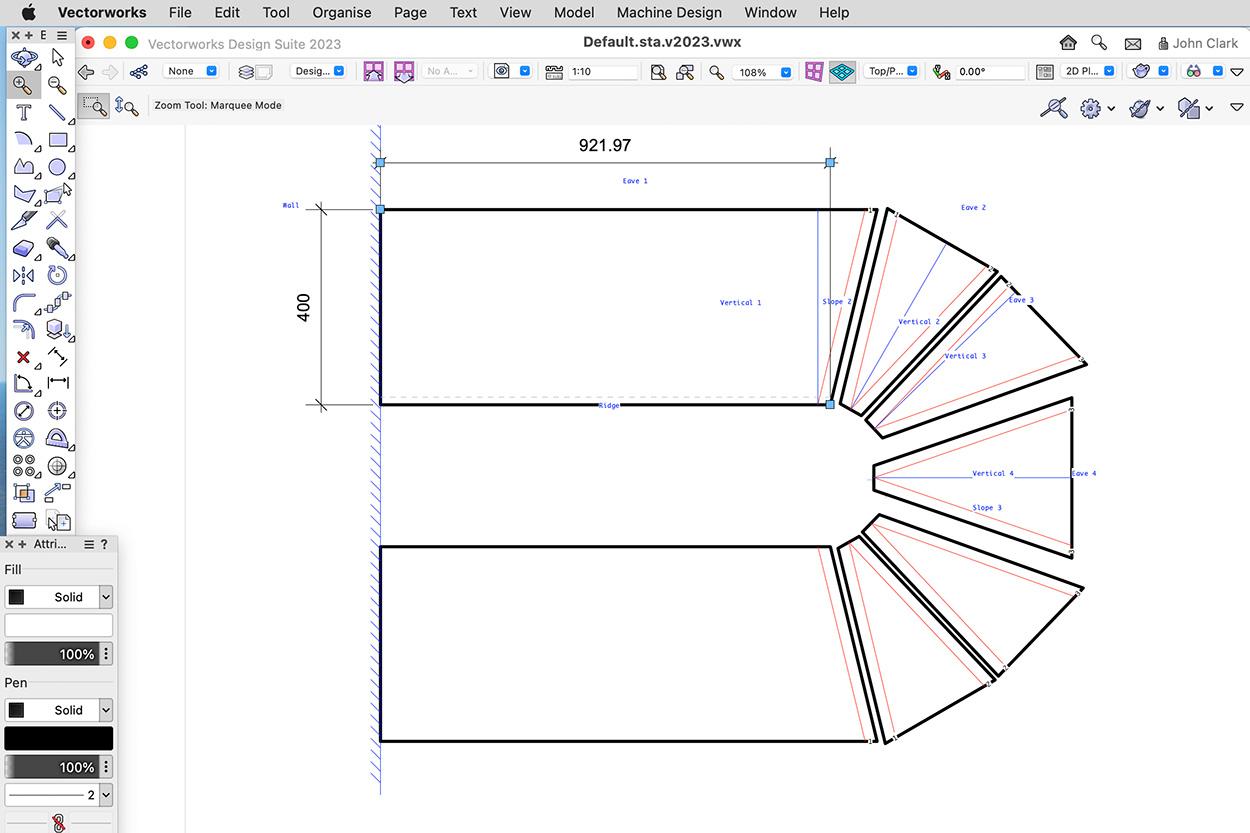

Truck curtains and tarpaulins are mostly made from wide roll materials and need a wide and long cutting table. However with Aeronaut's rapid pattern design parametric plug-ins and a wide span flatbed cutter, the complete design to cut process can be reduced to under 15 minutes.

Essential

The Elektron Mono is the automated cutter you want if you're on a budget. It's an industrial strength cutter designed for hard work, low maintenance and a very long lifespan. Fitted with one steered Cam-lock quick change tool holder, you can carry any cutting tools and swap them manually for drill punches, creasers or drag blades when the need arises. For wide span materials, see the Elektron Mono WS and for fabric narrower than 2050mm see the Elektron Mono LC.

Production

The Elektron Quattro is the most future proof and versatile production cutter for canvas and PVC work. The Elektron Quattro can carry 2, 3 or 4 steered Cam-lock quick change tool holders and comes with a marker pen holder. It can be fitted with inkjet print heads, additional markers and a Cyclops machine vision camera. It's a powerful and capable cutter able to handle the heaviest and most complex production cutting.

Aeronaut's Quick-change Tooling

All Aeronaut cutters feature quick-change tooling. The advantage of this starts with being able to change a sharp blade or punch off the cutting head, safely and quickly without fiddling about under the cutting head. Quick change tooling means you can always use the best tools for the job, even with a single tool axis cutter. Since tools can be exchanged in seconds, it's a huge production benefit.

New tools types are always being made and custom profiles and tools are also available on request for specific tasks.

Cam-lock Tools

Cam-lock tools are a proprietary Aeronaut design, modelled on the tool changing used on metalworking CNC machines. They have many advantages over basic bolt-on tools used on most competitive machines.

Cam-lock tools are secured with a quarter turn fastener below the cutting head. Plunge knives are actuated through the hollow tool axis and drill punch wads are ejected by a rod in the hollow tool axis.

Cam-lock tools are all unpowered and include rotary (pizza) blade holders (19mm, 28mm, 45mm), drag blades, plunge knives, creasing and scoring tools, and a Z-axis drill punches for ultimate flexibility.

Single steered tools

Cutters like the Elektron Mono, Elektron B1 and Ikon have only one steered tool axis.

The main benefit is lower cost. If you most of your work can be done with one cutting tool, then a single tool axis is fine.

With Cam-lock quick change tooling, you are not limited to just one tool on a single steered axis cutter. A manual tool change takes less than 15 seconds, so if tool changes are occasional, then a single tool cutter can be cost effective.

Tool axes intended for drill punching and creasing can optionally be configured to apply double pressure.

All Aeronaut cutters are fitted with a marker holder which can take anything from a ball point or fine marker to a paint pen. The pen plate can also carry an inkjet print head, another marker or a Cyclops machine vision camera which makes the single tool machines almost as versatile as a multi-tool cutter but at a lesser cost.

Multiple steered tools

With a multi-tool head like the Elektron Quattro or Elektron B2 you have the most versatile type of cutter. Each steered axis can be fitted with a different type of tool so all parts of a job can be cut with the optimum tool or when cutting abrasive materials, more than one cutting tool can be carried, increasing the time between blade changes.

Uniquely, with the Cam-lock tool system, each axis can function as a drill punch so a 4 tool head can carry three different punch sizes and a cutting tool.

Tool axes intended mainly for drill punches and creasing can optionally be configured to apply double pressure.

Tool changes are done automatically in software and take less than a second. This, over hundreds of tool changes a day, increases productivity over a single steered tool machine.

Because a multi-tool cutting head is slightly wider, the pen plate can carry more equipment including an inkjet print head, another marker or a Cyclops machine vision camera.

Software, Nesting and Technology

Contact Aeronaut

Get the facts from the factory direct. If you want advice on automated cutting, an offer on a complete cutting system or to arrange a demonstration, just ask!

Products

Technology

Special Machines

Matrelec HF Welders

Applications

Company

News

Contact Details

Aeronaut Automation

4-6 Tepko Road,

Terrey Hills,

New South Wales 2084

Australia.

Hours: 8:00 - 17:00 Australian Eastern Standard Time

Tel: +612 9450 0800

Sales: Sales@Aeronaut.org

Admin: Admin@Aeronaut.org

Support: Support@Aeronaut.org

Tech: Tech@Aeronaut.org