Aeronaut Automated Cutting Systems for Composites, Carbon and FRP

Aeronaut's cutting systems are used extensively in the world of composites. Carbon, Kevlar, glass fibre, sprint, pre-preg or dry fibre, the high cutting power of the Elektron chassis makes easy work of cutting composite materials.

Aeronaut supplies automated cutting systems, vacuum tables, debulking tables, cutting heads and machine vision systems right across the composites industry used in marine, aerospace, defence, recreational and transport industries, everywhere a reasonably priced, industrial strength cutter is required to do the cutting room work.

A 28mm rotary blade or an 18mm rotary blade for more detailed shapes, will cut almost any material used in composite work without breaking up the edge of cut piece the way that reciprocating blades do. The optional high pressure axis which can be fitted to most Aeronaut cutters can put down twice the pressure on the blade to handle the toughest multi-ply pre-preg.

The Tools of Your Trade

Essential

Aeronaut's entry level Elektron Mono LC or Ikon cutters set the standard for high performance automated cutters machines working with narrow composite materials, yet they're no more expensive than less capable machines. The Elektron Mono is intended as a full turnkey installation machine while the Ikon is an industrial strength cutter which you can install yourself.

Production

The Mikron 2 cutter is a fast, economical and very versatile cutter which is made in a range of sizes which suit just-in-time and lean manufacturing in the composites industry. It has two Cam-lock quick changed steered tools, a marker holder and comes as standard with a Cyclops machine vision camera and can be fitted with SiliconEye machine vision for tracing and digitising.

Versatility

The Mikron Elektron Quattro with 2, 3 or 4 steered tool axes can handle the most complex cutting tasks with ease. Use a 28mm rotary blade for most cuts and an 18mm rotary for details, a drag blade or punch tool for smaller cutouts and holes. Tools are changed automatically in software for consistently accurate, high speed production.

Cam-lock Quick Change Tools

On multi-tool machines like the Elektron Quattro, tools are changed automatically under software control. However Cam-lock tools can be changed by hand in a few seconds so you can fit the tools you need, when you need.

The Cam-lock tool range includes 18mm, 28mm and 45mm rotary blades, tangential or drag knives with various depth stops for normal and high friction materials, creasing and scoring tools in a wide range of profiles and drill-punch sizes from pin to over 25mm. Drill-punch inserts are easy to sharpen and exchange.

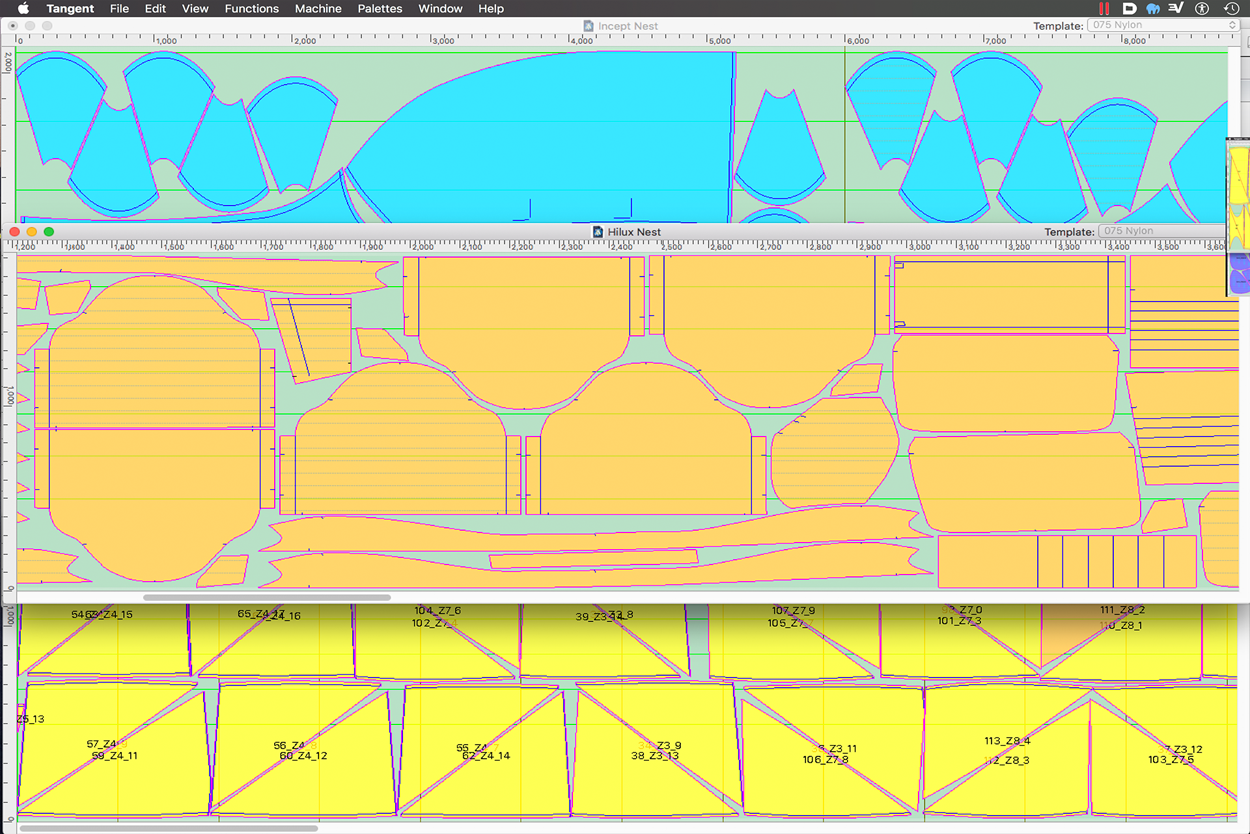

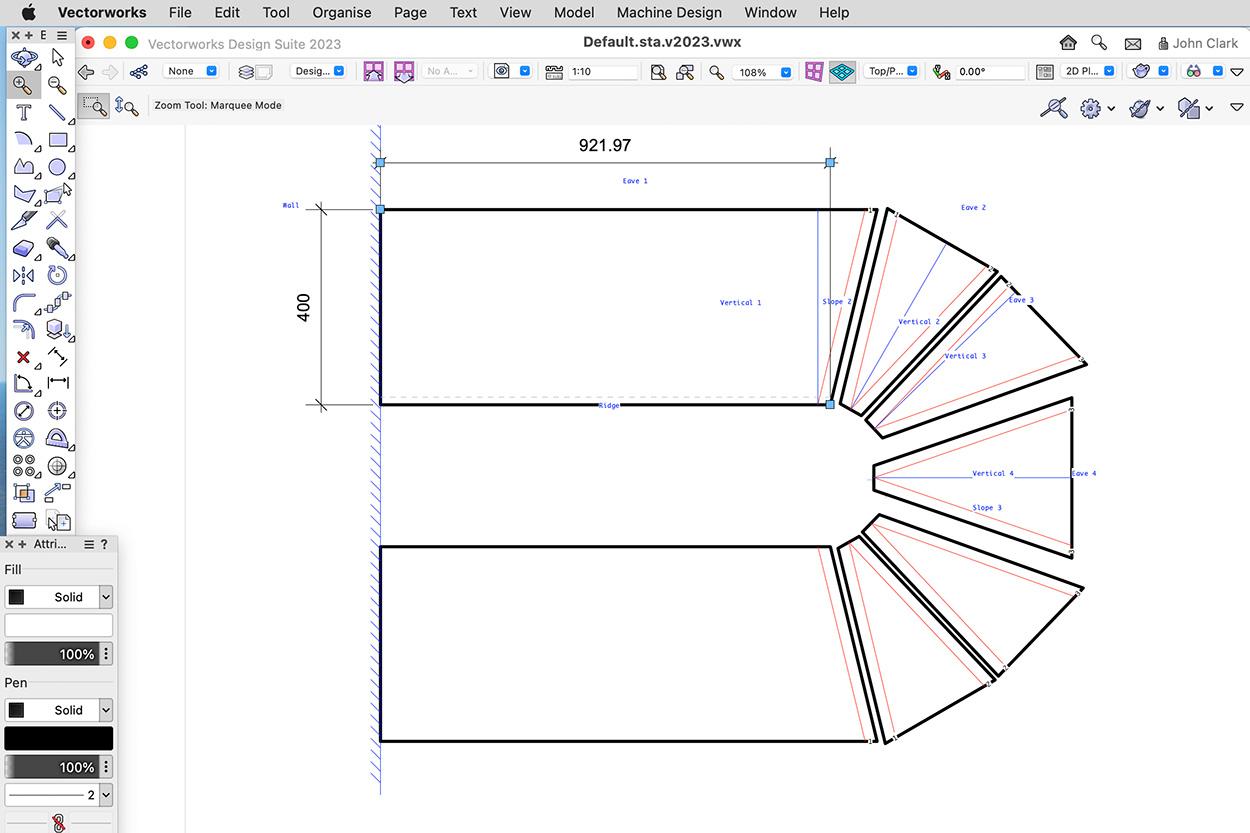

Software, Nesting and Technology

Contact Aeronaut

Get the facts from the factory direct. If you want advice on automated cutting, an offer on a complete cutting system or to arrange a demonstration, just ask!

Products

Technology

Special Machines

Matrelec HF Welders

Applications

Company

News

Contact Details

Aeronaut Automation

4-6 Tepko Road,

Terrey Hills,

New South Wales 2084

Australia.

Hours: 8:00 - 17:00 Australian Eastern Standard Time

Tel: +612 9450 0800

Sales: Sales@Aeronaut.org

Admin: Admin@Aeronaut.org

Support: Support@Aeronaut.org

Tech: Tech@Aeronaut.org