Bayonet Mount Quick-change Tools

The Tools of Your Trade

Why Bayonet Mount Tools?

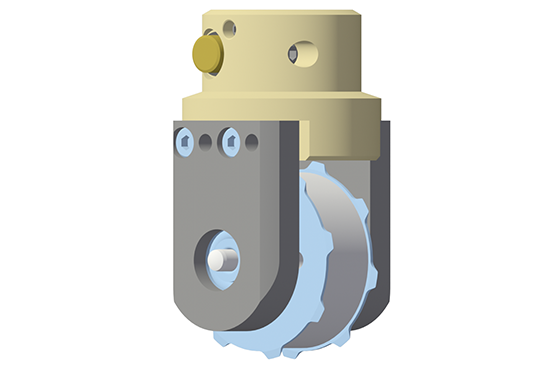

Bayonet tools are another Aeronaut innovation. Bayonet mounted tools are loaded from the top and locked in place with a quarter turn bayonet ring, similar to the way a lens locks in place on an SLR camera. Because bayonet tools load from above, larger static and powered tools can be carried.

- Quick change mounting in a few seconds.

- Static tools such as cutting and creasing tools can be carried.

- Thicker and more difficult materials can be cut with powered tools.

- Electrically powered tools like powered rotary and reciprocating or oscillating knives can be fitted.

- Pneumatically powered tools like long stroke oscillating blade tools can be fitted.

- Ultrasonic cut and crease tools can be fitted.

- Pneumatic plunge knives can be fitted.

- Bayonet tools effectively future-proof the machine. You can fit the tools you need for work in the future.

- Where a drill-punch tool is required, it can be fitted on the front of the cutting head.

Aeronaut developed its range of bayonet mount tools initially to work with corrugated packaging, but if you can cut and crease cardboard, you can cut and crease fabric for window blinds can't you? Well it turned out a bit more complicated than that but bayonet mounted tools for cut and creasing was the start of Aeronaut's window furnishing machines.

The Elektron B1 and Elektron B2 cutters used for packaging, ultrasonic cutting and sealing or textiles for window furnishings and cutting and sealing MLI for aerospace applications are just a few uses of bayonet tools.

Cutting, Creasing, Drilling and Punching

Powered Tools

The bayonet mount will take a lot of powered tool including reciprocating blade cutters (pneumatic and electrical), ultrasonic tools for cutting and sealing, small routing tools and drills and powered rotary blade holders.

Depth of cut is set by a micrometer adjustable foot or via the tool axis.

Reciprocating blade cutter. This electric powered tool has a short stroke, high speed reciprocating action and uses a lightweight titanium blade holder to take a wide range of commonly available and specialised blades.

Recipro cutters are commonly used when cutting corrugated board, corflute, leather, foam and other thick materials where accurate cutting is required.

The depth of cut is adjusted by the Teflon faced blade guide.

Reciprocating blade cutter. The pneumatically powered tool has a long stroke, moderate oscillating speed. The blade holder takes a wide range of commonly available tungsten blades in various profiles and lengths.

Recipro cutters are commonly used when cutting thick corrugated board, foam, insulation and other thick materials where accurate cutting is required.

The depth of cut is adjusted by the tool axis.

Ultrasonic Tools

Ultrasonic cutting tools are specialised tools which are part of the Elektron B1 Ultra and Elektron B2 Ultra cutting systems.

The Ultrasonic tool system consists of an ultrasonic generator, and mounted in the tool, a converter and sonotrode. The high frequency vibrations of this tuned system are used to melt and cut or seal the substrate.

The removable sonotrode is available in a range of shapes for cutting and sealing different synthetic materials.

Rotary Blade Tools

Tangentially steered rotary blade (pizza wheel) blades are the most common cutting tools used on most materials on all single and low ply cutting machines all around the world.

The rolling blade cuts with a shearing action which doesn't move materials much while cutting. The long exposed blade edge means long blade life on most materials. (Blade life is almost impossible to estimate bu… on PVC it might be days while on glass fibre, might be hours.)

28mm rotary blade. This the most widely used tool for most cut jobs. The blade geometry allows most shapes to be cut… see the notes on blade geometry below.

The blade support shoulders are available in a range of diameters to expose more or less blade and to allow discs to ride on the material surface if required.

Blade rotation can be locked with a set screw to allow the tool to be used as a soft drag knife.

Blades are reasonably priced and have a good working life on most materials.

Why call it a rotary blade? Well, after getting a cutter stuck in customs in the Balkans for some weeks because they thought a pizza blade cutter had something to do with food production, we decided a rotary blade was a safer name!

18mm rotary blade. This is the tool to use for detailed shapes. It's good for PVC, leather and other materials where you want to cut small diameter radii and limit overcut.

Blade support shoulders are available in a more limited range of diameters.

45mm rotary blade. This tool can be used for cutting thicker materials like foam rubber and for cutting simple and large patterns. The large diameter doesn't allow for fine details. (28mm tool shown for illustration.)

Blade support shoulders are available in a wide range of diameters.

Drag Blade Tools

Drag or Tangential blade holders take a range of different geometry blades from high quality solid carbide blades to simple craft blades.

Many blade holders will either take different blade geometries or inserts are available for this.

LC Drag Blade Holder. This holder will take most drag blade types with a flat back. The blade tip is indexed to the tool axis centre in the holder to make sure that the cut starts and ends correctly.

The blade depth is set by the screw depth stop base and the locking ring fixed so replacement blades are set to the correct depth.

Drag blade cut depth is set using a depth stop. Generally the depth stop is set and locked in place and this retains the cut depth over blade changes.

Depth stops are made from low-friction plastic and available in a range of shapes from the basic to the Mushroom blade holder with teflon insert.

Reciprocating blade cutter can be used as a plain drag blade tool when the power is disconnected. The teflon coated tool base acts as a blade guide and depth stop combined.

The bayonet mount plunge blade tool is self contained and incorporates the plunge mechanism and blade holder. Because the depth stop remains in contact with the material being cut throughout the process, the plunge tool is faster and more accurate than a conventional drag blade.

Plunge drag blade. This holder is the best drag blade option. The blade depth is set by an internal pneumatic mechanism pushes the blade holder insert down by a precise amount when cutting. The depth is set via an adjustment knob on the top of the tool.

Creasing and Scoring

These tools are functionally almost the same. Fabric workers tend to call them creasers while corrugated and packaging tend to call it scoring.

When scoring cardboard, the larger diameter tools are best since they don't crack the corrugated board's surface.

45mm Creasing tool. This tool is intended for creasing or scoring materials like corrugated board. Different roller profiles are available for different thicknesses of board and types of work.

Fabric creasing can take more pressure than cardboard so smaller creasing wheels are often used.

Crush cutting tools are heavy duty creasing tools with sharper profiles designed for crush cutting.

28mm Creasing holder. This tool is available with a range of profiles to suit creasing fabric and corrugated or plain board up to 7mm thick.

The 28mm diameter profile applies more force to the substrate.

Heavy Duty Creaser or Crush Cutter. This tool holder is for heavy duty creasing on fabric or crush cutting on a hard table top.

The hardened steel profiled discs are interchangeable and can be resharpened when required.

Drill Punches

A drill punch works by slightly turning the punch as it's lowered into the material and is far more efficient that a plain punch. the speed, pressure and duration of the process is software controlled. Wads are ejected from the punch using a solid rod ejector.

Drill Punch Holder. The tool consists of three parts. The top Cam-lock mechanism. The driver and punch holder and the punch insert itself. The punch holder and insert are quick-change and snap onto the drive dog.

Punch inserts are available in sizes from pin to over 25mm/1" in standard increments.

Special Tools

Where would we be without special tools? Of course Aeronaut can adapt tools for special purposes and even make entirely new ones to a customer's specification.

Providing the lower part of the tool can attach to the Cam-lock mechanism, most designs can be accommodated.

Pinking and Perforating Tools. Pinking and perforating are not always successful on an automated cutter partly because the cutter by its geometry, tends to rough up the cutting surface. However, with careful design of the blade area, perforating tools can work well for special applications.

Products

Technology

Special Machines

Matrelec HF Welders

Applications

Company

News

Contact Details

Aeronaut Automation

4-6 Tepko Road,

Terrey Hills,

New South Wales 2084

Australia.

Hours: 8:00 - 17:00 Australian Eastern Standard Time

Tel: +612 9450 0800

Sales: Sales@Aeronaut.org

Admin: Admin@Aeronaut.org

Support: Support@Aeronaut.org

Tech: Tech@Aeronaut.org