Matrelec Initial High-Frequency Welder Range

Matrelec's Initial HF range is ideal for welding, marking and cutting technical textiles such as PVC, PU, EVA sheets, PVC or PU coated fabrics, and any material with dielectric losses. These compact high-frequency welding machines are perfect for versatile production needs where jobs and materials are frequently changed.

The Initial range welders runs from the compact CCM30 single-user low-power welder to the powerful CP press. All have foot control, quick tool changes, variable power levels and the option to add impulse welding. These presses allow precise positioning of materials and welds and using templates, accurate, repeatable and traceable weld quality.

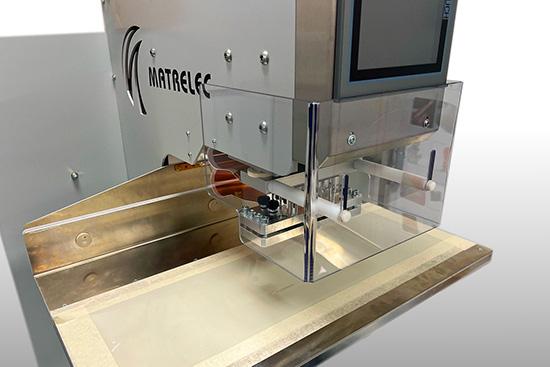

CCM30 Press - 3kW

This small press with built-in pedal control is ideal for single operator two-handed work. There is no earth plate allowing full access to the work area making the welding of small parts, details or finishes quick, precise and easy. Quick-change tooling and the ability do impulse welding as well as HF welding at 4 power levels makes the CCM30 a versatile addition to any factory.

For precision work this machine can be fitted with an enclosed automatic transfer table or a sleeve board for difficult parts such as tubes, sleeves or any other parts that cannot rest on a table.

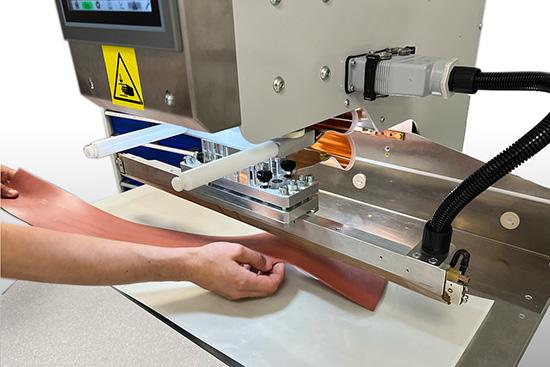

CCM80 Press - 6 to 8kW

Matrelec's CCM80 machines are high-frequency welding presses with a 420mm throat and no earth capacitor, allowing the space behind the electrode to be freed up. The CCM80 features quick tool attachment via T-slider, multiple power levels for using small tools and precise welds up to 800mm.

CCM80 welders are perfect for two people working together with the dedicated dual operator mode, easily accessible controls, and excellent work area visibility provided by the reduced height and width of the tool holder as well as the height of the clearance under the electrode, making face-to-face work easier.

C Press - 6 to 10kW

Matrelec's C welders with a 780mm depth behind the electrode are perfect for welding of large and bulky products as well as smaller items because of quick-change tools and multiple power levels. The wide bar allows accurate welding of lengths up to 800mm.

For long jobs, a mobile table can be added which avoids moving the material and thus prevents scratches clear materials. The option without earth plate, allows the use of 800 x 600 tools and impulse welding features are available.

CP Press - 10 to 15kW

Matrelec's CP welders, with 1500mm behind the electrode, are perfect for large products like truck curtains, tarps and liners. The control panel can be placed on either side of the press so there is good access all around the machine and the pedal operation allows work from three sides.

Airconditioning in the head allows welding on long lengths without over heating the electrode. The rigid bar allows precise welds with electrodes up to 1200mm long. Quick change tools are pneumatically clamped with optional dovetail slide or T-slot fitting.

Contact Aeronaut

Get the facts from the factory direct. If you want advice on automated cutting, an offer on a complete cutting system or to arrange a demonstration, just ask!

Products

Technology

Special Machines

Matrelec HF Welders

Applications

Company

News

Contact Details

Aeronaut Automation

4-6 Tepko Road,

Terrey Hills,

New South Wales 2084

Australia.

Hours: 8:00 - 17:00 Australian Eastern Standard Time

Tel: +612 9450 0800

Sales: Sales@Aeronaut.org

Admin: Admin@Aeronaut.org

Support: Support@Aeronaut.org

Tech: Tech@Aeronaut.org