Aeronaut Automated Cutting Systems for Pool Liners and Covers

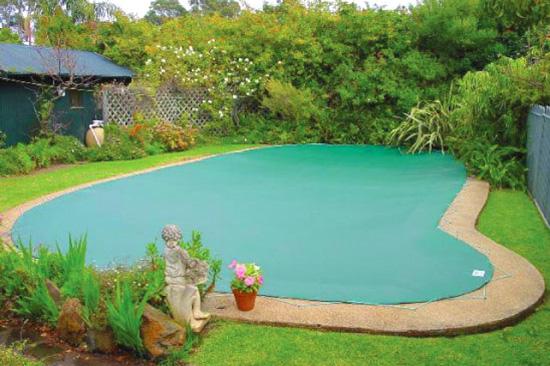

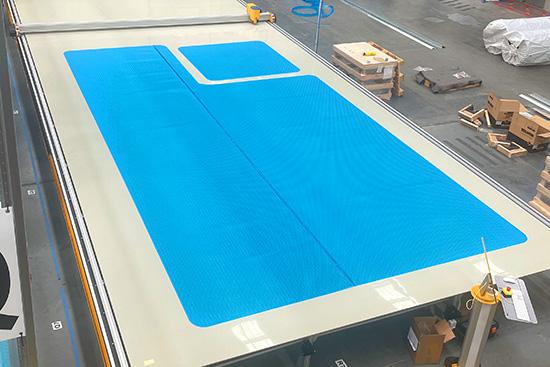

Large products made from technical textiles like swimming pool liners and covers perfect for cutting on a flatbed automated cutter. While pool liner materials are very stretchy and don't require precision cutting, the curves involved are easy to cut with a machine. Pool covers are more precise. Some fabricators cut panels and join them carefully, while others cut full size on a wide span vacuum table so joining is simplified.

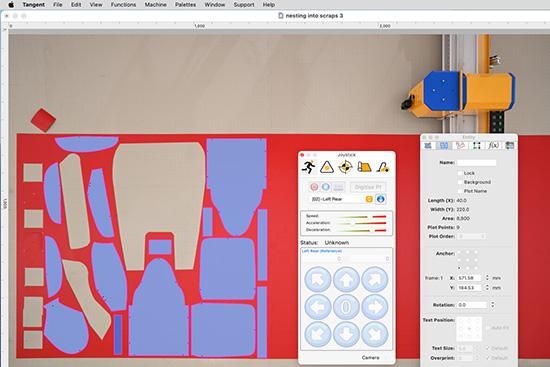

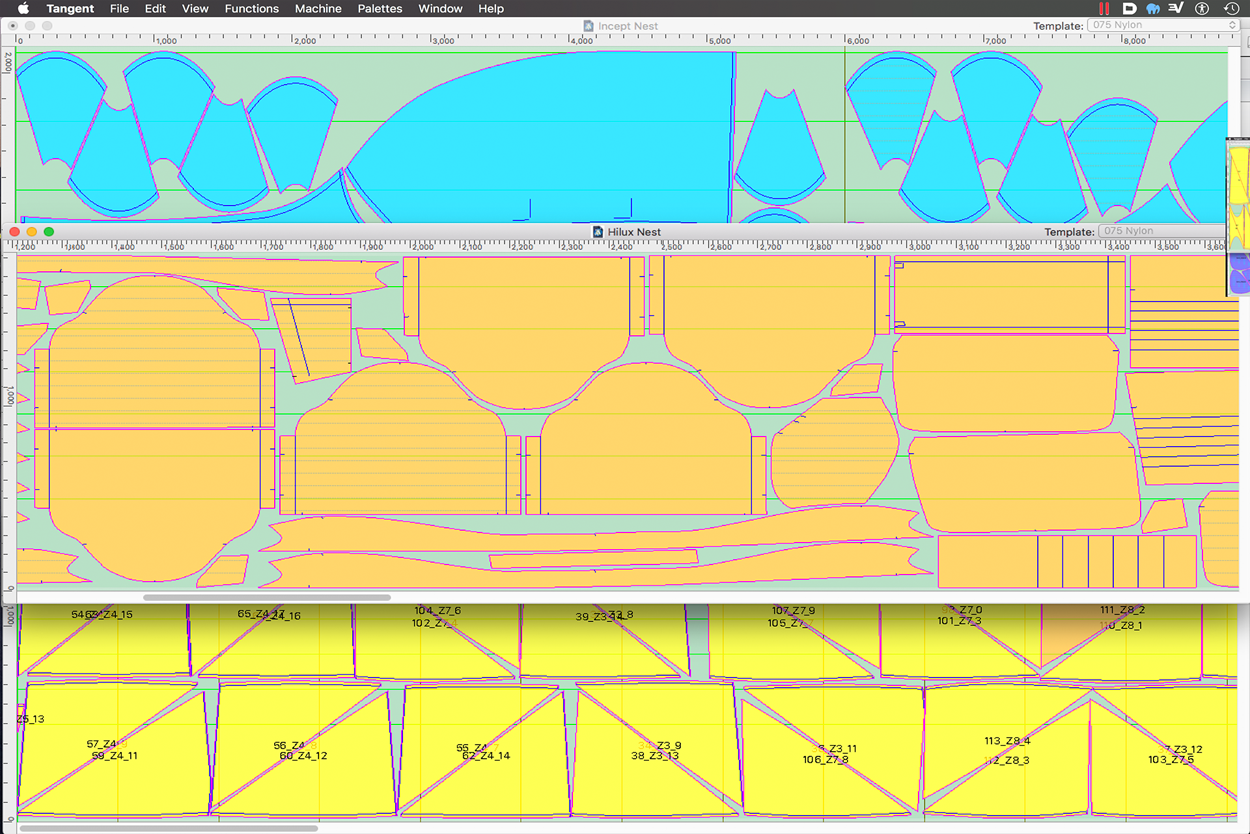

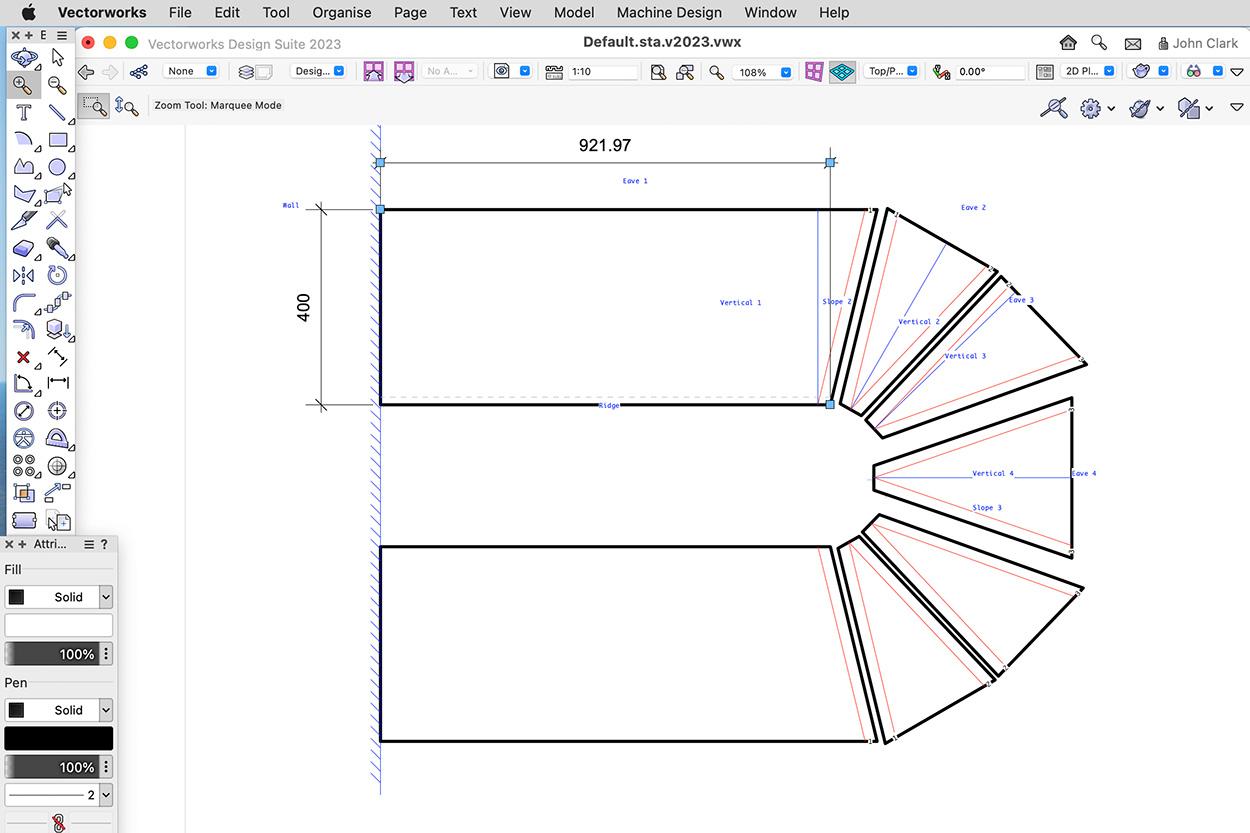

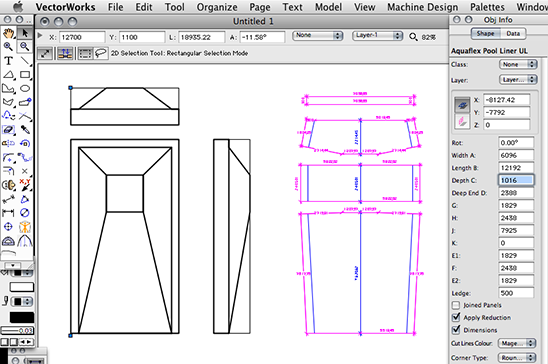

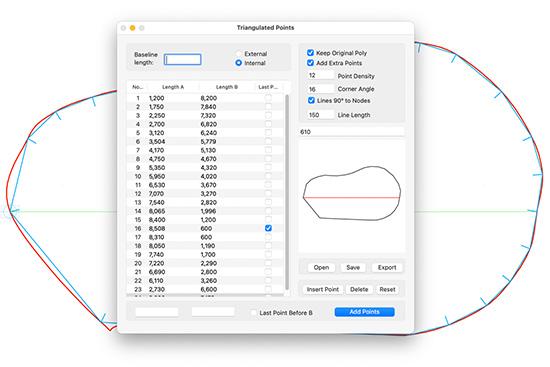

Rapid patterning for swimming pool liners and covers can be done in a number of ways. Measuring tools like the Prodim can be used for both liners and covers and export a CAD file which can be easily edited and cut. Conventionally measured surveyor's plans can be converted to CAD profiles using Aeronaut's Triangulated Points tool. Full patterns can be imported into Aeronaut's Tangent cutter control and nesting software where they can be split into fabric widths with seam allowances and strike-up marks added.

The Tools of Your Trade

Essential

For the automated cutting of most pool liner and covers, a 28mm rotary blade will do the job. A 45mm rotary blade will easily and accurately cut the simple shapes of thick insulated pool cover material. Depending on the fabric widths, the Elektron Mono LC or Elektron Mono WS are the essential tools for this work.

Versatility

If you need maximum versatility and cut more than simple pool liners and covers, then an Elektron Quattro fitted with 2, 3 or 4 steered tools is the right cutter. Mark, punch, crease and cut with multiple tools on an accurate and reliable automated cutter which will effectively future proof your cutting work.

Cam-lock Quick Change Tools

Cam-lock tools can be changed by hand in a few seconds so you can fit the tools you need, when you need. On the Elektron Quattro, tools are changed automatically under software control.

The Cam-lock tool range includes 18mm, 28mm and 45mm rotary blades, tangential or drag knives with various depth stops for normal and high friction materials, creasing and scoring tools in a wide range of profiles and drill-punch sizes from pin to over 25mm. Drill-punch inserts are easy to sharpen and exchange.

Software, Nesting and Technology

Contact Aeronaut

Get the facts from the factory direct. If you want advice on automated cutting, an offer on a complete cutting system or to arrange a demonstration, just ask!

Products

Technology

Special Machines

Matrelec HF Welders

Applications

Company

News

Contact Details

Aeronaut Automation

4-6 Tepko Road,

Terrey Hills,

New South Wales 2084

Australia.

Hours: 8:00 - 17:00 Australian Eastern Standard Time

Tel: +612 9450 0800

Sales: Sales@Aeronaut.org

Admin: Admin@Aeronaut.org

Support: Support@Aeronaut.org

Tech: Tech@Aeronaut.org